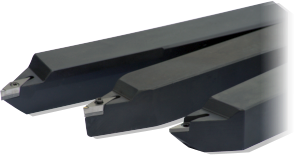

DAVID RICHARDS ENGINEERING LTD

ULTRA HARD CUTTING TOOLS

Specialists in the application of Ultra Hard Cutting Tool Technology

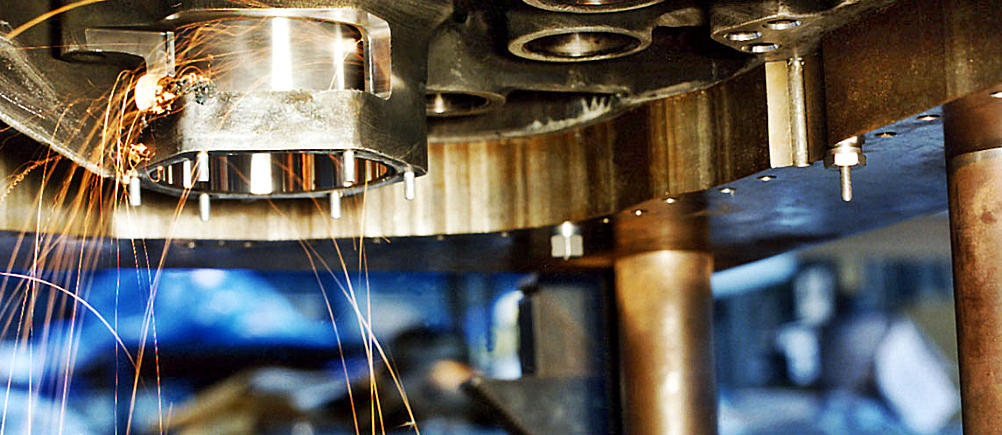

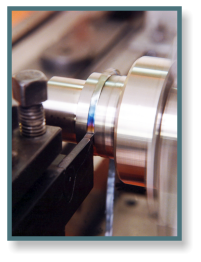

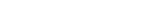

Since 1989 David Richards have developed a reputation for providing production engineering solutions to a diversity of problems. Using

the latest CNC grinding and spark erosion techniques, a wide range of standard PCBN and PCD tools are manufactured to stock. Over

many years of operation, we have been involved in many new and challenging projects. To gain the benefit of our experience, contact the

experts at David Richards.

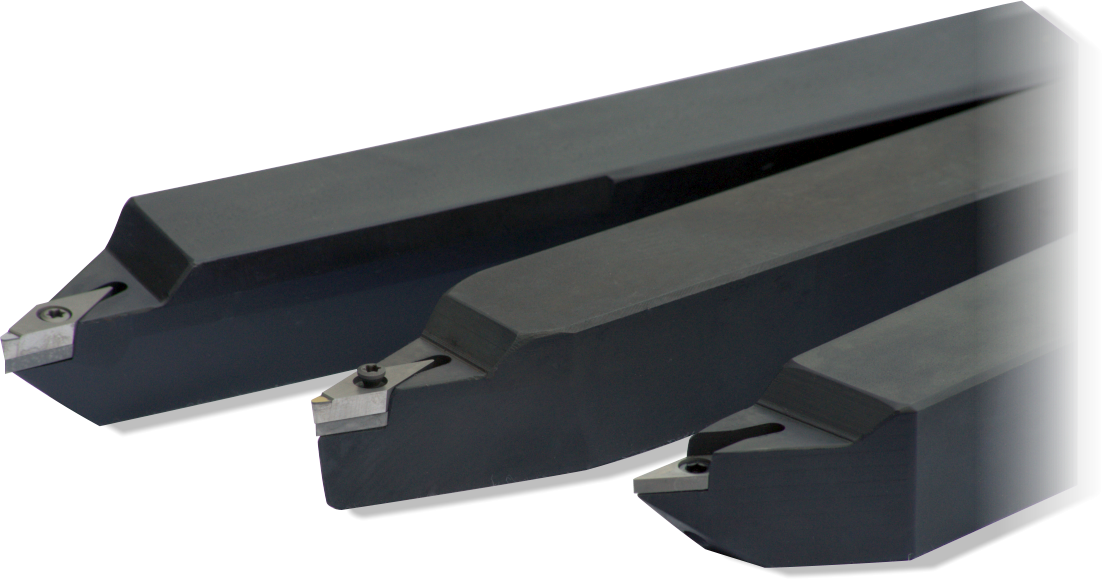

Where standard products are not ideal or cost effective, special tools, tool holders, and cutting tool inserts are manufactured to suit the

application and supplied as soon as possible. Our customer base includes companies from all sectors of manufacturing industry including,

automotive, aerospace, machine tool, press and mould tool and woodworking.

This website does NOT use Cookies for any analytical purposes

DAVID RICHARDS ENGINEERING

ULTRA HARD CUTTING TOOLS

Specialists in the application of Ultra Hard Cutting Tool Technology

Since 1989 David Richards have developed a

reputation for providing production engineering

solutions to a diversity of problems. Using the

latest CNC grinding and spark erosion

techniques, a wide range of standard PCBN

and PCD tools are manufactured to stock.

Over many years of operation, we have been

involved in many new and challenging projects.

To gain the benefit of our experience, contact

the experts at David Richards.

Where standard products are not ideal or cost

effective, special tools, tool holders, and cutting

tool inserts are manufactured to suit the

application and supplied as soon as possible.

Our customer base includes companies from all

sectors of manufacturing industry including,

automotive, aerospace, machine tool, press and

mould tool and woodworking.

Specialists in the application of

Ultra Hard Cutting Tool Technology

Since 1989 David Richards have developed a reputation for providing production

engineering solutions to a diversity of problems. Using the latest CNC grinding and

spark erosion techniques, a wide range of standard PCBN and PCD tools are

manufactured to stock.

Over many years of operation, we have been involved in many new and challenging

projects. To gain the benefit of our experience, contact the experts at David

Richards.

Where standard products are not ideal or cost effective, special tools, tool holders,

and cutting tool inserts are manufactured to suit the application and supplied as soon

as possible. Our customer base includes companies from all sectors of manufacturing

industry including, automotive, aerospace, machine tool, press and mould tool and

woodworking.

ULTRA HARD CUTTING TOOLS

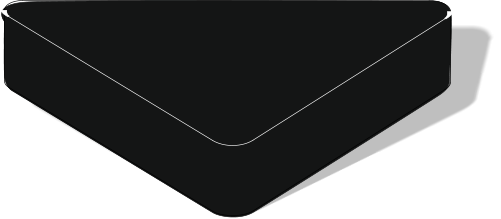

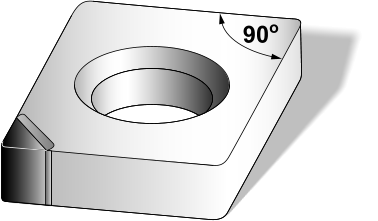

DR-100 is a fully solid high CBN content material and is

used for heavy machining applications, where high stock

removal rates provide an attractive alternative to

conventional techniques.

Brazeable High CBN Content

DR-75

DR-85

DR-95

DR-400

DR-650

DR-900

DR-75 machines Cast Iron that is not fully Pearlitic. DR-85

and DR-95 have complex ceramic binders designed to give

exceptional tool life machining Cast Iron. DR-400 is the

toughest CBN grade we offer. DR-650 contains TiN and

has a larger CBN particle size but retains the ability to keep

heat in the shear zone for finish machining. DR-900 is

brazeable DR-100

Low CBN Content

DR-50

DR-450

DR-500

Rough Machining

DR-100

Diamond, cubic carbon,

is the hardest, most

abrasive resistant

material known to man.

It is therefore an ideal

tool material -

Unfortunately, in the

presence of heat and

iron, nickel or cobalt,

diamond transforms to

it’s hexagonal form,

graphite.

This is why ferrous materials are not generally machined with diamond.

The second hardest material, Cubic Boron Nitride (CBN), is created by man, using temperatures and pressures like those for diamond synthesis. However, it does not have this inherent weakness when it

comes to the machining of ferrous materials. PCBN cutting tools machine hardened steels with apparent ease because, using relatively high surface speeds, heat is generated at the point of cutting. So the

PCBN tool cuts locally softened material.

The heat is carried away by the swarf or chip, which becomes brittle and harmless, and the PCBN tool, which has a high co-efficient of thermal conductivity.

If a light cut is required, however, a tool with a high CBN content conducts too much heat away from the shear zone and the conditions for efficient machining cannot be achieved.

The properties of a PCBN cutting Tool grade are generally dependant on a number of factors:

•

The concentration of the CBN particles and any ceramic binder

•

The size of the CBN particles in the matrix

•

The size of the ceramic particles in the matrix

•

The type of ceramic binder used

David Richards offers 10 grades of CBN material

DR-50

Brazed tools and indexable inserts for finishing with continuous cutting or favourable interrupted cutting.

DR-500

Brazed Tools and indexable inserts for finishing with continuous cutting or very favourable interrupted cutting. The hardest PCBN we supply with the greatest tool life under ideal conditions.

DR-450

Brazed tools and indexable inserts for finishing with favourable interrupted cutting or extreme surface finish requirements.

DR-650

Brazed tools and indexable inserts for finishing with less favourable interrupted cutting and semi-finishing.

DR-75

Brazed Tools and indexable inserts for Cast Iron that is not fully Pearlitic.

DR-85

Brazed tools and indexable inserts for cast iron machining and semi-finishing where the solid CBN format of DR-100 is not applicable.

DR-95

Brazed Tools and Indexable inserts for heat treated Cast Iron and machining of Powder Metals and Cobalt and Nickel Chrome alloys.

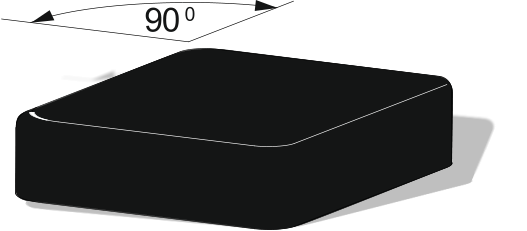

DR-100

Fully solid PCBN for roughing and cast-iron machining.

DR-400

Brazed tools and indexable inserts for extremely difficult materials and unfavourable cutting conditions.

DR-900

Brazed tools and indexable inserts for roughing with severe interrupted cutting and cast-iron machining.

Grade Selection

A harder grade will always achieve a longer tool life, so it is always best to use the hardest grade that will complete the application. It is always

worthwhile, spending some time resources, ensuring that the machine tool, tool holder, and work holding are in as good a condition as possible.

However, as the system ages and things become worn, it may be necessary to switch to a tougher grade to accommodate a resulting lack of rigidity.

DAVID RICHARDS ENGINEERING

ULTRA HARD CUTTING TOOLS

What is Polycrystalline Cubic Boron Nitride?

Diamond, cubic carbon, is the hardest, most abrasive resistant material known to man.

It is therefore an ideal tool material.

Unfortunately, in the presence of heat and iron, nickel or cobalt, diamond transforms to hexagonal form,

graphite.

This is why ferrous materials are not generally machined with diamond.

DR-100 is a fully solid high CBN content material and is

used for heavy machining applications, where high stock

removal rates provide an attractive alternative to

conventional techniques.

Brazeable High CBN Content -

DR-75

DR-85

DR-95

DR-400

DR-650

DR-900

Low CBN Content -

DR-50

DR-450

DR-500

Rough Machining - DR-100

DR-75 machines Cast Iron that is not fully Pearlitic. DR-85

and DR-95 have complex ceramic binders designed to give

exceptional tool life machining Cast Iron. DR-400 is the

toughest CBN grade we offer. DR-650 contains TiN and

has a larger CBN particle size but retains the ability to keep

heat in the shear zone for finish machining. DR-900 is

brazeable DR-100 ………

All these grades have a low CBN content making them

ideal for precision finish machining. DR-500 is the hardest

CBN we supply and gives exceptional tool life. DR-50 is

tougher and performs well in less than ideal conditions.

DR-450 has a smaller particle size that makes it tougher

and capable of exceptional surface finishes.

The second hardest material, Cubic Boron Nitride (CBN), is created by man, using temperatures and pressures like those for

diamond synthesis. However, it does not have this inherent weakness when it comes to the machining of ferrous materials. PCBN

cutting tools machine hardened steels with apparent ease because, using relatively high surface speeds, heat is generated at the

point of cutting. So the PCBN tool cuts locally softened material.

The heat is carried away by the swarf or chip, which becomes brittle and harmless, and the PCBN tool, which has a high co-efficient

of thermal conductivity.

If a light cut is required, however, a tool with a high CBN content conducts too much heat away from the shear zone and the

conditions for efficient machining cannot be achieved.

The properties of a PCBN cutting Tool grade are generally dependant on a number of factors:

•

The concentration of the CBN particles and any ceramic binder

•

The size of the CBN particles in the matrix

•

The size of the ceramic particles in the matrix

•

The type of ceramic binder used

David Richards offers 10 grades of CBN material

DR-50

Brazed tools and indexable inserts for finishing with continuous cutting or favourable interrupted cutting.

DR-500

Brazed Tools and indexable inserts for finishing with continuous cutting or very favourable interrupted cutting.

The hardest PCBN we supply with the greatest tool life under ideal conditions.

DR-450

Brazed tools and indexable inserts for finishing with favourable interrupted cutting or extreme

surface finish requirements.

DR-650

Brazed tools and indexable inserts for finishing with less favourable interrupted cutting and semi-finishing.

DR-75

Brazed Tools and indexable inserts for Cast Iron that is not fully Pearlitic.

DR-85

Brazed tools and indexable inserts for cast iron machining and semi-finishing where the solid CBN format

of DR-100 is not applicable.

DR-95

Brazed Tools and Indexable inserts for heat treated Cast Iron and machining of Powder Metals and Cobalt and

Nickel Chrome alloys.

DR-100

Fully solid PCBN for roughing and cast-iron machining.

DR-400

Brazed tools and indexable inserts for extremely difficult materials and unfavourable cutting conditions.

DR-900

Brazed tools and indexable inserts for roughing with severe interrupted cutting and cast-iron machining.

Grade Selection

A harder grade will always achieve a longer tool life, so it is always best to use the hardest grade that will complete the application.

It is always worthwhile, spending some time resources, ensuring that the machine tool, tool holder, and work holding are in as

good a condition as possible.

However, as the system ages and things become worn, it may be necessary to switch to a tougher grade to accommodate a

resulting lack of rigidity.

Diamond, cubic carbon, is the hardest, most abrasive resistant material

known to man.

It is therefore an ideal tool material.

Unfortunately, in the presence of heat and iron, nickel or cobalt,

diamond transforms to hexagonal form, graphite.

This is why ferrous materials are not generally machined with diamond.

The second hardest material, Cubic Boron Nitride (CBN), is created by man, using

temperatures and pressures like those for diamond synthesis. However, it does not have

this inherent weakness when it comes to the machining of ferrous materials. PCBN

cutting tools machine hardened steels with apparent ease because, using relatively high

surface speeds, heat is generated at the point of cutting. So the PCBN tool cuts locally

softened material.

The heat is carried away by the swarf or chip, which becomes brittle and harmless, and

the PCBN tool, which has a high co-efficient of thermal conductivity.

If a light cut is required, however, a tool with a high CBN content conducts too much heat

away from the shear zone and the conditions for efficient machining cannot be achieved.

The properties of a PCBN cutting Tool grade are generally dependant on a

number of factors:

•

The concentration of the CBN particles and any ceramic binder

•

The size of the CBN particles in the matrix

•

The size of the ceramic particles in the matrix

•

The type of ceramic binder used

David Richards offers 10 grades of CBN material

DR-50

Brazed tools and indexable inserts for finishing with continuous cutting or

favourable interrupted cutting.

DR-500 Brazed Tools and indexable inserts for finishing with continuous cutting or

very favourable interrupted cutting.

The hardest PCBN we supply with the greatest tool life under ideal conditions.

DR-450 Brazed tools and indexable inserts for finishing with favourable interrupted

cutting or extreme surface finish requirements.

DR-650 Brazed tools and indexable inserts for finishing with less favourable interrupted

cutting and semi-finishing.

DR-75

Brazed Tools and indexable inserts for Cast Iron that is not fully Pearlitic.

DR-85 Brazed tools and indexable inserts for cast iron machining and semi-finishing

where the solid CBN format of DR-100 is not applicable.

DR-95

Brazed Tools and Indexable inserts for heat treated Cast Iron and machining

of Powder Metals and Cobalt and Nickel Chrome alloys.

DR-100 Fully solid PCBN for roughing and cast-iron machining.

DR-400 Brazed tools and indexable inserts for extremely difficult materials and

unfavourable cutting conditions.

DR-900 Brazed tools and indexable inserts for roughing with severe interrupted cutting

and cast-iron machining.

Grade Selection

A harder grade will always achieve a longer tool life, so it is always best to use the

hardest grade that will complete the application. It is always worthwhile, spending some

time resources, ensuring that the machine tool, tool holder, and work holding are in as

good a condition as possible.

However, as the system ages and things become worn, it may be necessary to switch to

a tougher grade to accommodate a resulting lack of rigidity.

DR-100 is a fully solid high CBN content material and is used for

heavy machining applications, where high stock removal rates

provide an attractive alternative to conventional techniques.

Rough Machining - DR-100

DR-75 machines Cast Iron that is not fully Pearlitic. DR-85 and

DR-95 have complex ceramic binders designed to give exceptional

tool life machining Cast Iron. DR-400 is the toughest CBN grade

we offer. DR-650 contains TiN and has a larger CBN particle

size but retains the ability to keep

heat in the shear zone for finish

machining. DR-900 is brazeable

DR-100 ………

Brazeable High CBN Content - DR-85, 95, 400, 650 & 900

All these grades have a low CBN content making them ideal for

precision finish machining. DR-500 is the hardest CBN we supply

and gives exceptional tool life. DR-50 is tougher and performs

well in less than ideal conditions. DR-450 has a smaller particle

size that makes it tougher and capable of exceptional surface

finishes.

Low CBN Content - DR-50, 450 & 500

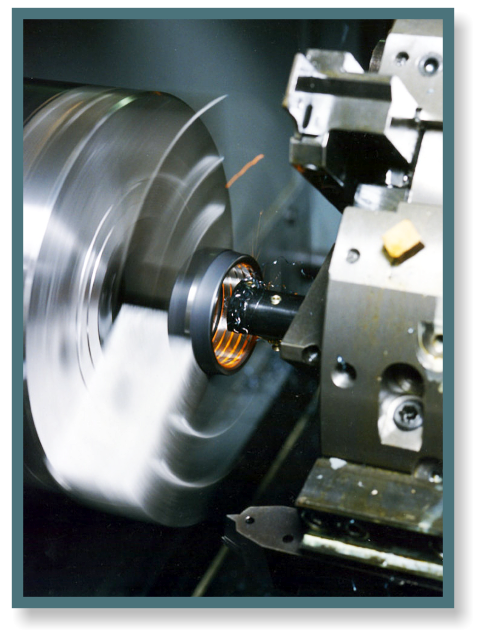

PCBN cutting tools machine hardened steels with apparent ease because, using relatively high surface speeds, heat is generated at the point of cutting so the PCBN tool cuts locally softened

material. The heat is carried away by the swarf, which becomes brittle and harmless, and the PCBN tool, which has a high co-efficient of thermal conductivity. If a light cut is required,

however, a tool with a high CBN content conducts too much heat away from the shear zone and the conditions for efficient machining cannot be achieved.

DR-50, 450 & 500 have a low CBN content. The individual CBN particles are isolated within a ceramic matrix. This gives the materials a lower thermal conductivity. Low CBN tools can, therefore, keep sufficient

heat at the cutting point to enable the optimum cutting conditions to be achieved. The result is greater wear resistance in finish cutting operations.

Low CBN can be used to provide a productive and cost effective alternative to grinding. Tolerances achieved are comparable but machining time can be dramatically reduced. The accuracy and surface finish

achieved will be dependant on the machine used. Vibration will affect the surface finish and free play will limit the tolerances that can be achieved.

When turning or boring hollow sections, chucking pressure should be reduced to encourage roundness and concentricity. Although the component may be hard, cutting forces will be very small.

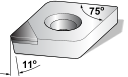

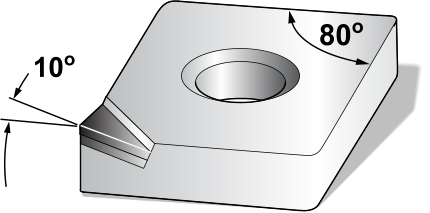

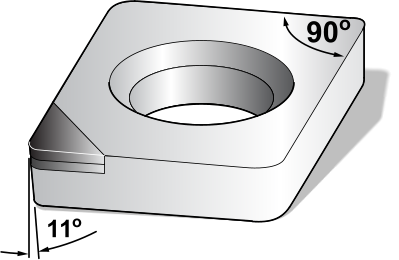

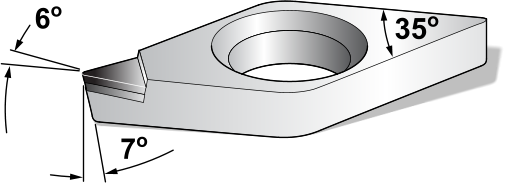

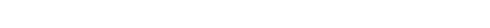

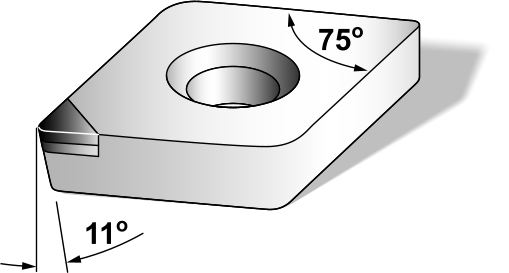

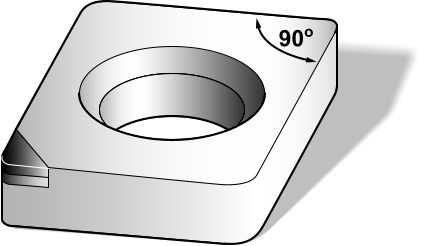

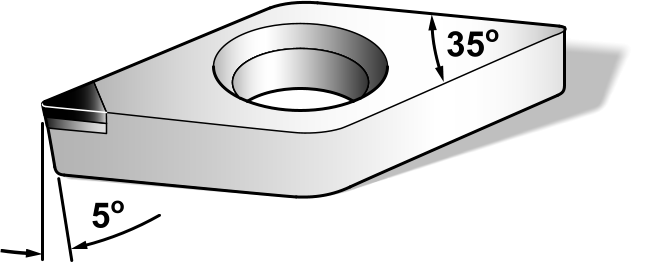

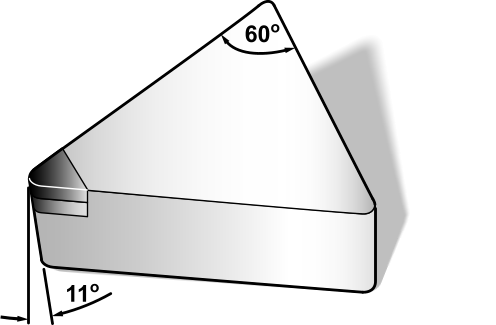

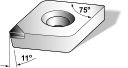

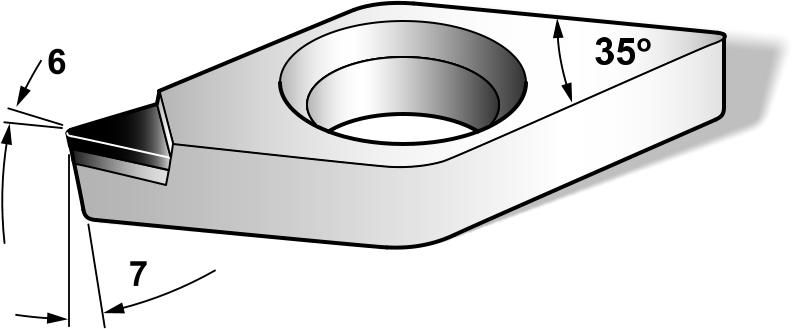

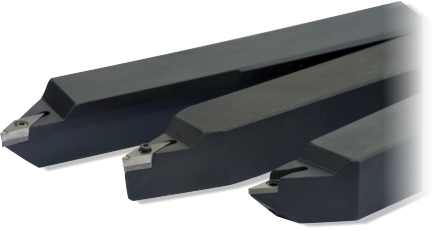

In most cases, even when very light cuts are required, low CBN tools employ negative rake geometry to provide a strong cutting edge.

Due to the nature of cutting, however, cutting forces are still very small.

When turning or boring hollow sections, chucking pressure should be reduced to encourage roundness and concentricity. Although the component may be hard, cutting forces will be very small.

DR-500 contains TiC and is the hardest finishing grade with the best ultimate tool life under ideal conditions.

DR-50 has a higher CBN content and is tougher, making it suitable for less than ideal applications.

DR-450 contains TiN and has a smaller CBN particle size. This results in a tougher material that produces marginally better surface finishes. DR-450 is only used when the application is not successfully

achieved using DR-50.

Coolant has little effect on the cutting mechanism since the heat generated in the shear zone is sufficient to vaporise any coolant provided.

Coolant does however serve three major purposes:-

•

Although most of the heat essential for efficient cutting exits with the chip, any increase in the temperature of the component will make accurate measuring difficult. Coolant can be used

to reduce this effect.

•

Coolant can be used to drive away any swarf which might interfere with the cutting edge, particularly in boring operations. Coolant can help to reduce vibration, especially where rigidity

is limited.

•

Where interrupted cutting occurs, coolant should not be used as this will thermally shock the CBN tool as it comes out of cut, resulting in premature failure. Although interrupted cutting

with coolant will never improve tool life, it is possible to use coolant machining hardened steel with DR-450 and coolant can be used machining cast iron, that is not hardened, under all

conditions.

For finish-machining of hardened steels and certain softer ferrous materials:

•

Surface and through hardened steels

•

High speed steels

•

Bearing steels

•

Hot - work die steel

•

Cold - work tool steel

•

Grey and chilled cast iron

•

Sintered Irons

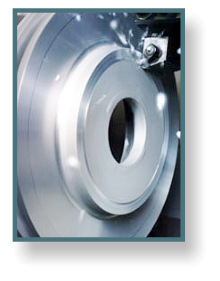

Through hardened En31 Bearing Steel Machining

Applying

DR-50, 450 & 500 Applications

Typical Machining Parameters

WHEN NOT TO USE ‘CBN’

Application Examples

For stock removal of hard (45-68 Hrc) and certain softer ferrous materials:

•

Martensitic cast irons - Ni-hard - High Chrome irons Chilled cast irons

•

Fully hardened cold-work tool steels

•

Bearing steels

•

High speed steels

•

Martenstic stainless steels

•

Cobalt and nickel based hard facing alloys

•

Fully pearlitic grey cast iron

DR-50/450 & 500 Applications

Through hardened En31 Bearing Steel Machining

PCBN cutting tools machine hardened steels with apparent ease because, using relatively high surface

speeds, heat is generated at the point of cutting so the PCBN tool cuts locally softened material. The

heat is carried away by the swarf, which becomes brittle and harmless, and the PCBN tool, which has a

high co-efficient of thermal conductivity. If a light cut is required, however, a tool with a high CBN

content conducts too much heat away from the shear zone and the conditions for efficient machining

cannot be achieved.

DR-50, 450 & 500 have a low CBN content. The individual CBN particles are isolated within a ceramic matrix. This

gives the materials a lower thermal conductivity. Low CBN tools can, therefore, keep sufficient heat at the cutting

point to enable the optimum cutting conditions to be achieved. The result is greater wear resistance in

finish cutting operations.

Low CBN can be used to provide a productive and cost effective alternative to grinding. Tolerances achieved are

comparable but machining time can be dramatically reduced. The accuracy and surface finish achieved will be

dependant on the machine used. Vibration will affect the surface finish and free play will limit the tolerances that

can be achieved.

When turning or boring hollow sections, chucking pressure should be reduced to encourage roundness and

concentricity. Although the component may be hard, cutting forces will be very small.

In most cases, even when very light cuts are required, low CBN tools employ negative rake geometry to provide a

strong cutting edge.

Due to the nature of cutting, however, cutting forces are still very small.

When turning or boring hollow sections, chucking pressure should be reduced to encourage roundness and

concentricity. Although the component may be hard, cutting forces will be very small.

DR-500 contains TiC and is the hardest finishing grade with the best ultimate tool life under ideal conditions.

DR-50 has a higher CBN content and is tougher, making it suitable for less than ideal applications.

DR-450 contains TiN and has a smaller CBN particle size. This results in a tougher material that produces

marginally better surface finishes. DR-450 is only used when the application is not successfully

achieved using DR-50.

Coolant has little effect on the cutting mechanism since the heat generated in the shear zone is

sufficient to vaporise any coolant provided.

Coolant does however serve three major purposes:-

•

Although most of the heat essential for efficient cutting exits with the chip, any increase in the

temperature of the component will make accurate measuring difficult. Coolant can be used to

reduce this effect.

•

Coolant can be used to drive away any swarf which might interfere with the cutting edge,

particularly in boring operations. Coolant can help to reduce vibration, especially where

rigidity is limited.

•

Where interrupted cutting occurs, coolant should not be used as this will thermally shock the CBN

tool as it comes out of cut, resulting in premature failure. Although interrupted cutting with coolant

will never improve tool life, it is possible to use coolant machining hardened steel with DR-450 and

coolant can be used machining cast iron, that is not hardened, under all conditions.

Applying

Typical Machining Parameters

WHEN NOT TO USE ‘CBN’

Application Examples

For stock removal of hard (45-68 Hrc)

and certain softer ferrous materials:

DR-85/95/400 & 650 Applications

Through hardened En31 Bearing

Steel Machining

•

Martensitic cast irons - Ni-hard - High

Chrome irons Chilled cast irons

•

Fully hardened cold-work tool steels

•

Bearing steels

•

High speed steels

•

Martenstic stainless steels

•

Cobalt and nickel based hard facing alloys

•

Fully pearlitic grey cast iron

Applying

PCBN cutting tools machine hardened steels with apparent ease because,

using relatively high surface speeds, heat is generated at the point of cutting

so the PCBN tool cuts locally softened material. The heat is carried away by

the swarf, which becomes brittle and harmless, and the PCBN tool, which

has a high co-efficient of thermal conductivity. If a light cut is required,

however, a tool with a high CBN content conducts too much heat away from

the shear zone and the conditions for efficient machining cannot be achieved.

DR-50, 450 & 500 have a low CBN content. The individual CBN particles are isolated

within a ceramic matrix. This gives the materials a lower thermal conductivity. Low

CBN tools can, therefore, keep sufficient heat at the cutting point to enable the

optimum cutting conditions to be achieved. The result is greater wear resistance in

finish cutting operations.

Low CBN can be used to provide a productive and cost effective alternative to

grinding. Tolerances achieved are comparable but machining time can be dramatically

reduced. The accuracy and surface finish achieved will be dependant on the machine

used. Vibration will affect the surface finish and free play will limit the tolerances that

can be achieved.

When turning or boring hollow sections, chucking pressure should be reduced to

encourage roundness and concentricity. Although the component may be hard, cutting

forces will be very small.

In most cases, even when very light cuts are required, low CBN tools employ negative

rake geometry to provide a strong cutting edge.

Due to the nature of cutting, however, cutting forces are still very small.

When turning or boring hollow sections, chucking pressure should be reduced to

encourage roundness and concentricity. Although the component may be hard, cutting

forces will be very small.

DR-500 contains TiC and is the hardest finishing grade with the best ultimate tool life

under ideal conditions.

DR-50 has a higher CBN content and is tougher, making it suitable for less than ideal

applications.

DR-450 contains TiN and has a smaller CBN particle size. This results in a tougher

material that produces marginally better surface finishes. DR-450 is only used when

the application is not successfully

achieved using DR-50.

Coolant has little effect on the cutting mechanism since the heat generated

in the shear zone is sufficient to vaporise any coolant provided.

Coolant does however serve three major purposes:-

•

Although most of the heat essential for efficient cutting exits with the

chip, any increase in the temperature of the component will make

accurate measuring difficult. Coolant can be used to

reduce this effect.

•

Coolant can be used to drive away any swarf which might interfere with

the cutting edge,

particularly in boring operations. Coolant can help to reduce vibration,

especially where

rigidity is limited.

•

Where interrupted cutting occurs, coolant should not be used as this will

thermally shock the CBN tool as it comes out of cut, resulting in premature

failure. Although interrupted cutting with coolant will never improve tool

life, it is possible to use coolant machining hardened steel with DR-450

and coolant can be used machining cast iron, that is not hardened, under

all conditions.

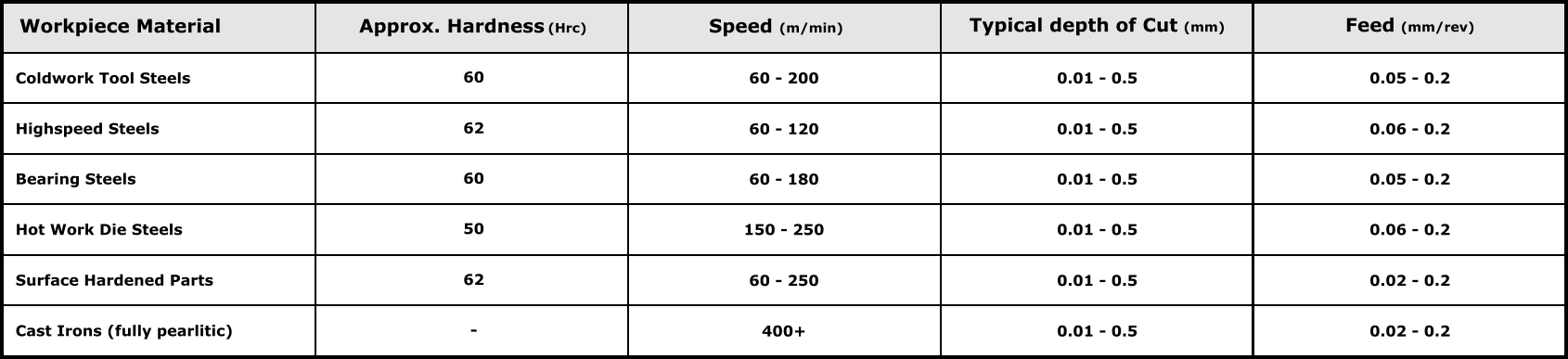

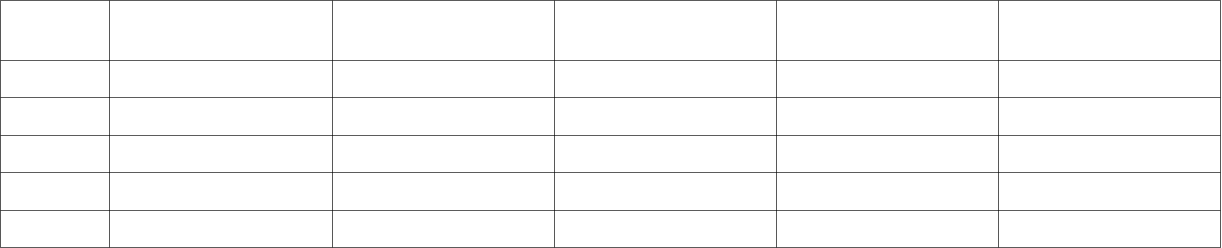

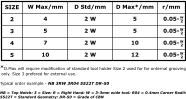

Typical Machining Parameters

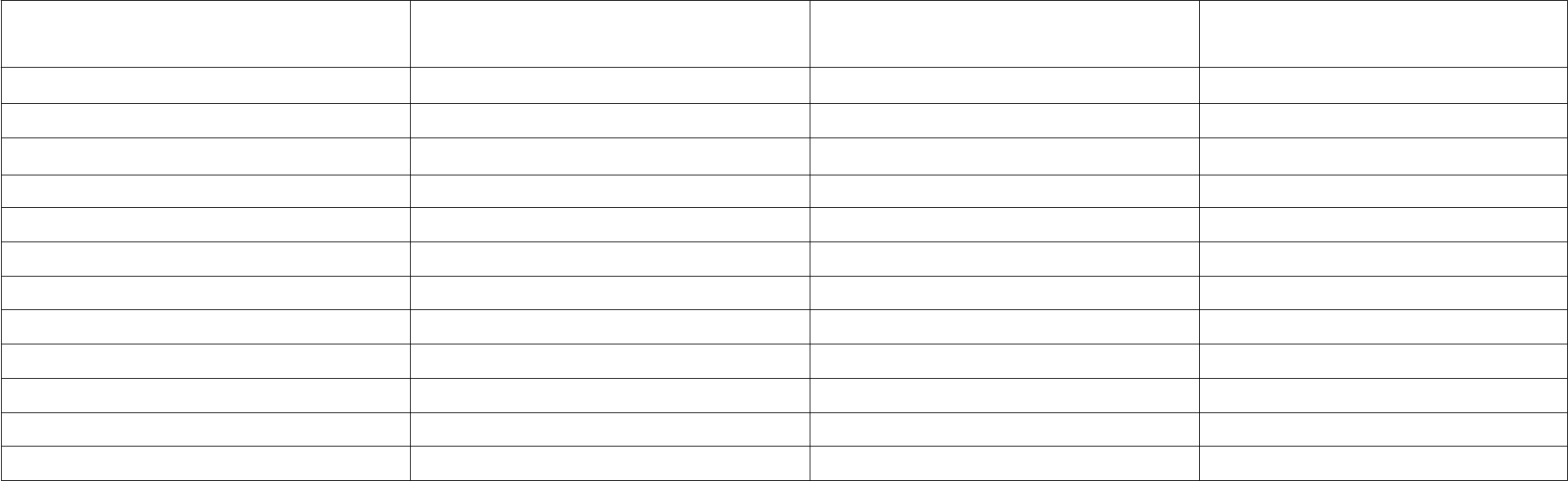

Workpiece Material

Speed (m/min)

Coldwork Tool Steels

60

Typical depth of Cut (mm)

Feed (mm/rev)

Approximate Hardness (Hrc)

Highspeed Steels

Bearing Steels

Hot Work Die Steels

Surface Hardened Parts

Cast Irons (fully pearlitic)

60 - 200

0.01 - 0.5

0.05 - 0.2

62

60 - 120

0.01 - 0.5

0.06 - 0.2

60

60 - 180

0.01 - 0.5

0.05 - 0.2

50

150 - 250

0.01 - 0.5

0.06 - 0.2

62

60 - 250

0.01 - 0.5

0.02 - 0.2

-

400+

0.01 - 0.5

0.02 - 0.2

WHEN NOT TO

USE ‘CBN’

Application Examples

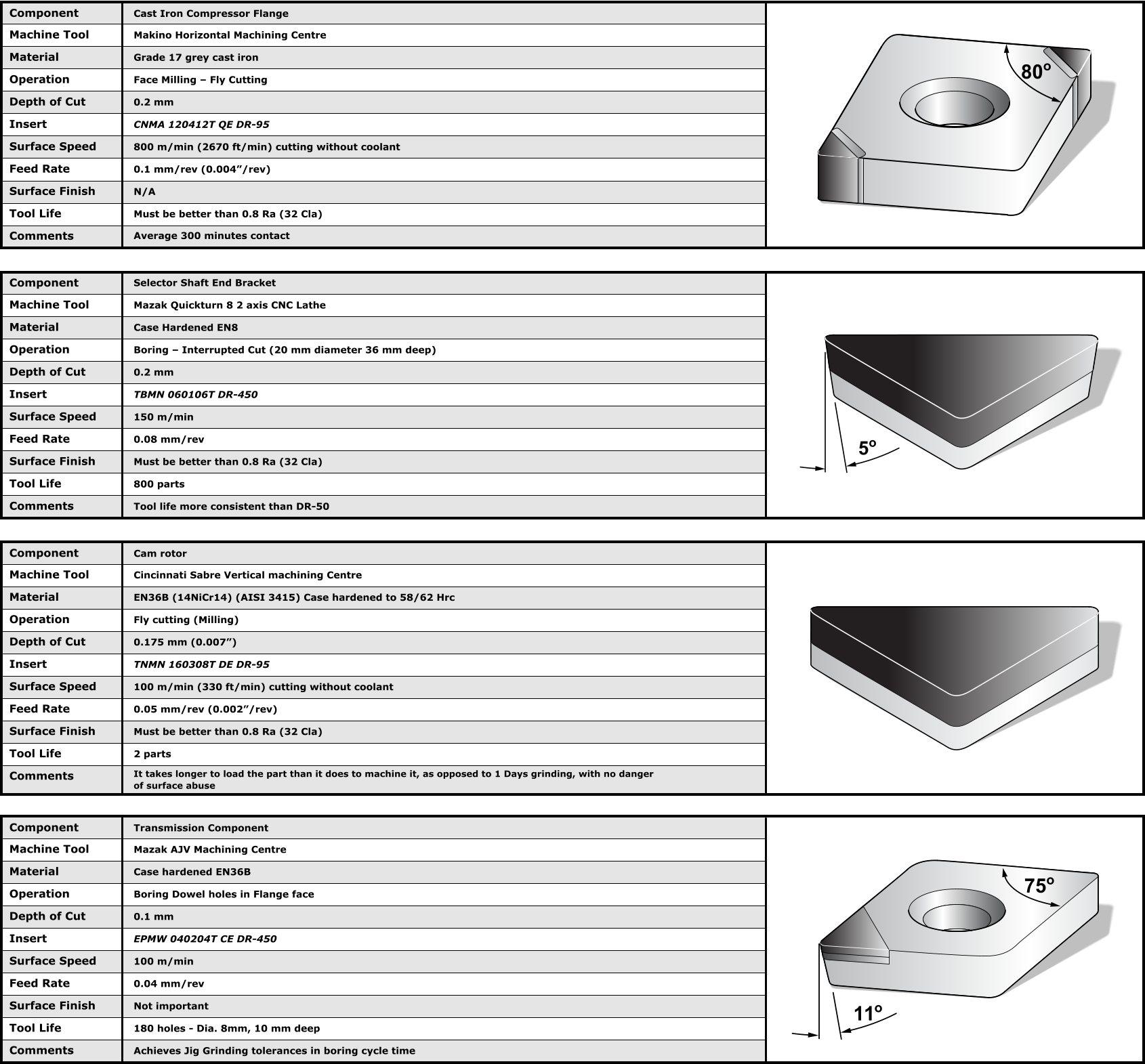

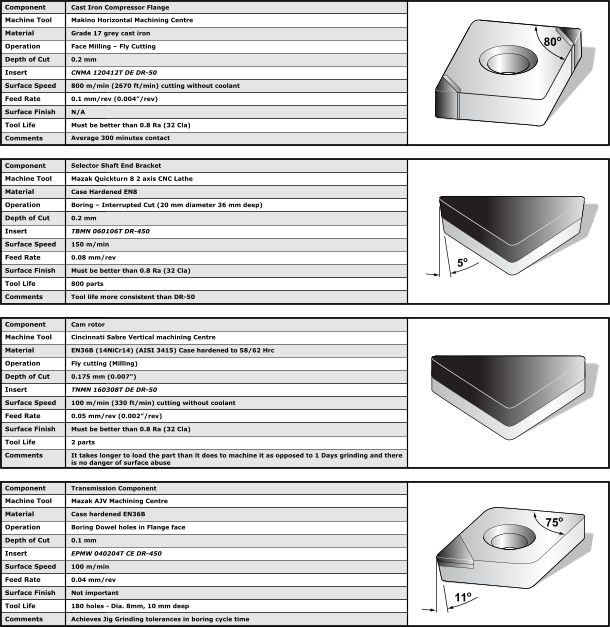

Cast Iron Compressor Flange

Makino Horizontal Machining Centre

Grade 17 grey cast iron

Face Milling – Fly Cutting

0.2 mm

CNMA 120412T DE DR-50

800 m/min (2670 ft/min) cutting without coolant

0.1 mm/rev (0.004”/rev)

N/A

Must be better than 0.8 Ra (32 Cla)

Average 300 minutes contact

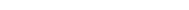

Selector Shaft End Bracket

Mazak Quickturn 8 2 axis CNC Lathe

Case Hardened EN8

Boring – Interrupted Cut (20 mm diameter 36 mm deep)

0.2 mm

TBMN 060106T DR-450

150 m/min

0.08 mm/rev

Must be better than 0.8 Ra (32 Cla)

800 parts

Tool life more consistent than DR-50

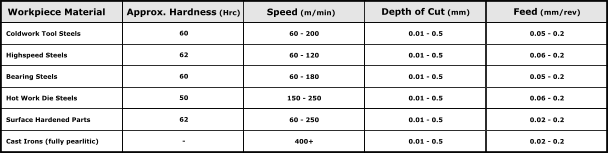

Cam rotor

Cincinnati Sabre Vertical machining Centre

EN36B (14NiCr14) (AISI 3415) Case hardened to 58/62 Hrc

Fly cutting (Milling)

0.175 mm (0.007”)

TNMN 160308T DE DR-50

100 m/min (330 ft/min) cutting without coolant

0.05 mm/rev (0.002”/rev)

Must be better than 0.8 Ra (32 Cla)

2 parts

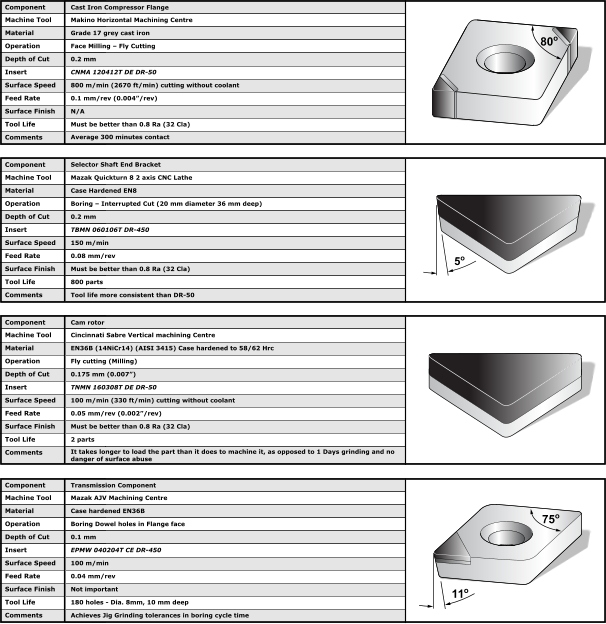

Transmission Component

Mazak AJV Machining Centre

Case hardened EN36B

Boring Dowel holes in Flange face

0.1 mm

EPMW 040204T CE DR-450

100 m/min

0.04 mm/rev

Not important

180 holes - Dia. 8mm, 10 mm deep

Achieves Jig Grinding tolerances in boring cycle time

Takes longer to load part than to machine it, as opposed to 1 Days grinding &

there is no danger of surface abuse

APPLICATIONS

DR-75, 85, 95, 400, 650 & 900

DR-75, 85, 95, 400, 650 & 900, are high CBN content materials, diffusion bonded at the manufacturing stage to a tungsten carbide substrate. This substrate enables flexibility in tool fabrication,

making it possible to apply a high PCBN content material where the solid indexable format of DR-100 is not suitable.

DR-75, 85, 95 & 650 are high PCBN cutting grades and machine hardened steels with apparent ease because, using relatively high surface speeds, heat is generated at the point of cutting so that the PCBN

tool cuts locally softened material. The heat is carried away from the workpiece by the chip, which rapidly air-cools to provide a brittle and harmless swarf, and the CBN tool, which has a high thermal

conductivity. This leaves the component cool, with its hardness unaffected.

DR-75 will machine Cast Iron that is not fully Pearlitic. It is not so vulnerable to Adhesion of sticky Ferrite.

DR-85 works well machining Pearlitic Grey Cast Irons. Excellent tool life can be achieved especially in finish milling and boring. DR-85 also provides good tool life machining high

alloy Powder Metal components.

DR-95 works well machining Pearlitic Grey Cast irons but Excels machining heat treated, chilled and alloyed cast irons. It is also recommended for Cobalt Chrome and Nickel Chrome alloys

DR-650 contains TiN and has a larger CBN particle size. This is a tougher grade that still maintains the ability to achieve small depths of cut, whilst still achieving efficient machining.

It works well interrupted cutting.

DR-400 is a high CBN content material with very good toughness. It is used when nothing else will work due to unstable cutting conditions or severe interrupted cutting.

DR-900 is DR-100 with a Tungsten Carbide substrate. It is useful for making tools that can be used where the solid Cutting Tool Insert format of DR-100 is not applicable

Although these grades are tough, vibration or deflection will result in reduced tool life and poor quality components. While they have been used on some very antiquated machines with excellent results,

rigidity is essential for success. Tool holders should be as large as possible and in good condition. Coolant has little effect on the cutting mechanism since the heat generated in the shear zone is sufficient to

vaporise any coolant provided.

Coolant does, however, serve two major purposes:-

If a substantial amount of material is to be removed, and a number of passes will be required, or any heating of the component will make measuring the part difficult, coolant can be used to stabilize the

temperature of the workpiece. Coolant can be used to drive the swarf away from the shear zone where it might interfere with the cutting edge. Coolant should not be used for interrupted cutting any

hardened materials.

Grooving induction hardened Stub Axle

For rough and semi-finish turning, milling, grooving and boring of hardened

ferrous and certain softer ferrous materials:-

•

Martensitic cast irons - Ni-hard - High chrome Chilled and heat treated cast irons

•

Fully hardened cold-work tool steels

•

Bearing steels

•

High speed steels (continuous cutting only)

•

Martensitic stainless steels

•

Cobalt and nickel based hard facing alloys

•

Fully pearlitic grey cast iron

•

Cast Iron with a Ferrite Content

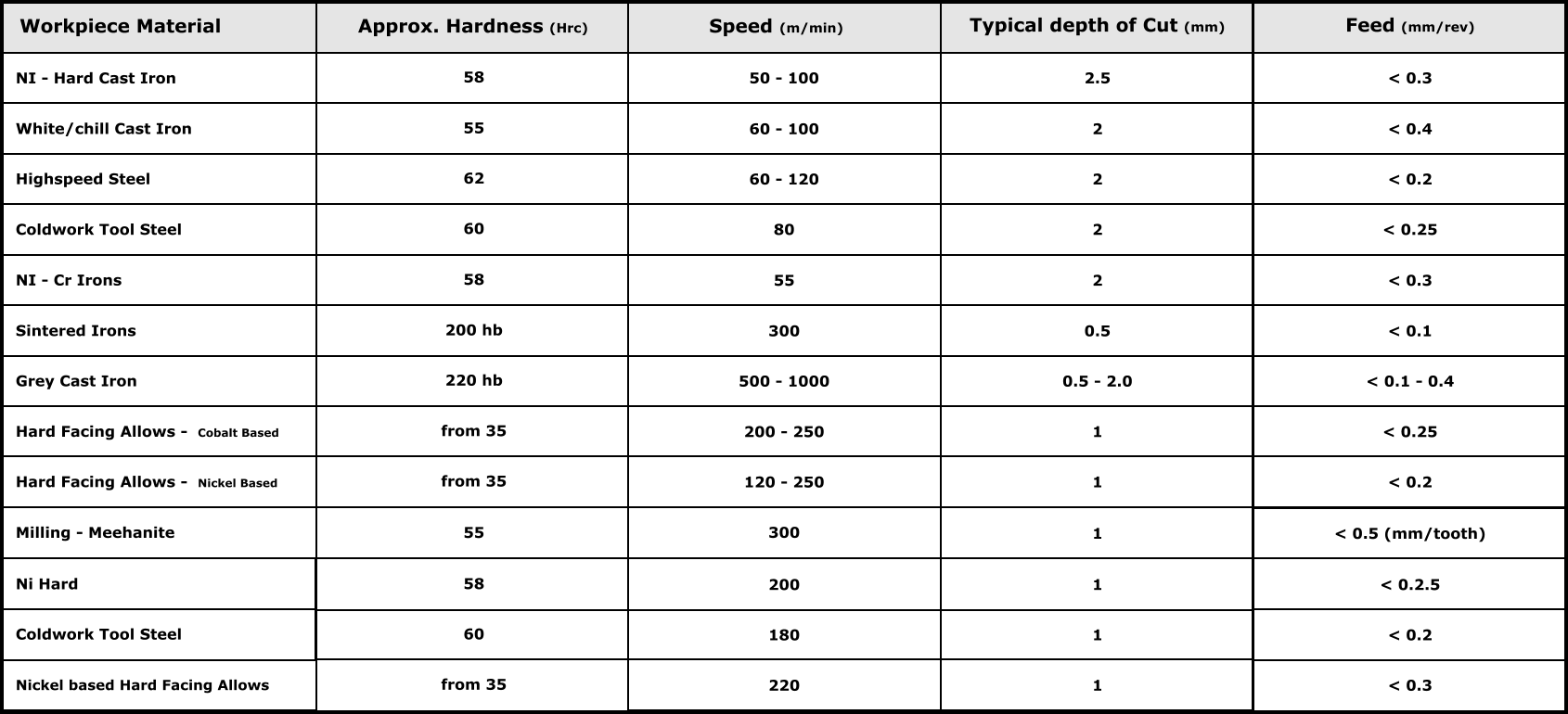

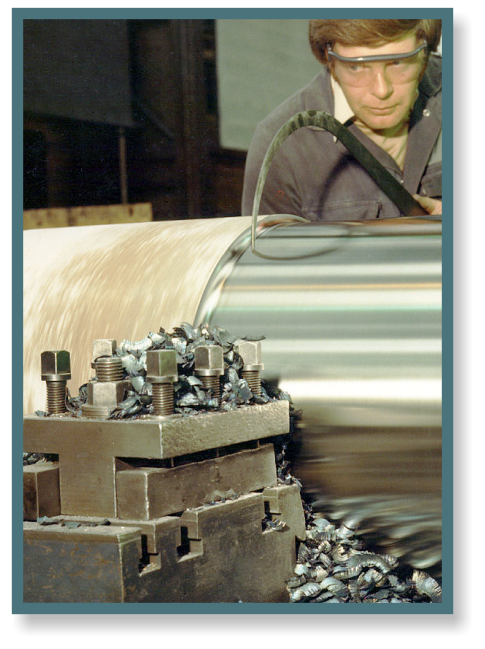

Typical Machining Parameters

Application Examples

WHEN NOT TO USE ‘CBN’

For rough and semi-finish turning, milling, grooving and boring of

hardened ferrous and certain softer ferrous materials:-

•

Martensitic cast irons - Ni-hard - High chrome

Chilled and heat treated cast irons

•

Fully hardened cold-work tool steels

•

Bearing steels

•

High speed steels (continuous cutting only)

•

Martensitic stainless steels

•

Cobalt and nickel based hard facing alloys

•

Fully pearlitic grey cast iron

DR-85/95/400 & 650 Applications

Grooving induction hardened Stub Axle

DR-75, 85, 95, 400, 650 & 900, are high CBN content materials, diffusion bonded at the manufacturing stage to a

tungsten carbide substrate. This substrate enables flexibility in tool fabrication,

making it possible to apply a high PCBN content material where the solid indexable format of DR-100 is not suitable.

DR-75, 85, 95 & 650 are high PCBN cutting grades and machine hardened steels with apparent ease because, using

relatively high surface speeds, heat is generated at the point of cutting so that the PCBN tool cuts locally softened

material. The heat is carried away from the workpiece by the chip, which rapidly air-cools to provide a brittle and

harmless swarf, and the CBN tool, which has a high thermal conductivity. This leaves the component cool, with its

hardness unaffected.

DR-75 will machine Cast Iron that is not fully Pearlitic. It is not so vulnerable to Adhesion of sticky Ferrite.

DR-85 works well machining Pearlitic Grey Cast Irons. Excellent tool life can be achieved especially in finish milling and

boring. DR-85 also provides good tool life machining high alloy Powder Metal components.

DR-95 works well machining Pearlitic Grey Cast irons but Excels machining heat treated, chilled and alloyed cast irons.

It is also recommended for Cobalt Chrome and Nickel Chrome alloys.

DR-650 contains TiN and has a larger CBN particle size. This is a tougher grade that still maintains the ability to achieve

small depths of cut, whilst still achieving efficient machining. It works well interrupted cutting.

DR-400 is a high CBN content material with very good toughness. It is used when nothing else will work due to

unstable cutting conditions or severe interrupted cutting.

DR-900 is DR-100 with a Tungsten Carbide substrate. It is useful for making tools that can be used where the solid

Cutting Tool Insert format of DR-100 is not applicable.

Although these grades are tough, vibration or deflection will result in reduced tool life and poor quality components.

While they have been used on some very antiquated machines with excellent results, rigidity is essential for success.

Tool holders should be as large as possible and in good condition. Coolant has little effect on the cutting mechanism

since the heat generated in the shear zone is sufficient to vaporise any coolant provided.

Coolant does, however, serve two major purposes:-

If a substantial amount of material is to be removed, and a number of passes will be required, or any heating of the

component will make measuring the part difficult, coolant can be used to stabilize the temperature of the workpiece.

Coolant can be used to drive the swarf away from the shear zone where it might interfere with the cutting edge.

Coolant should not be used for interrupted cutting any hardened materials.

Applying

Typical Machining Parameters

Application Examples

WHEN NOT TO USE ‘CBN’

For rough and semi-finish turning,milling,

grooving and boring of hardened ferrous

and certain softer ferrous materials:-

Grooving induction hardened Stub Axle

•

Martensitic cast irons - Ni-hard - High

chrome Chilled and heat treated cast irons

•

Fully hardened cold-work tool steels

•

Bearing steels

•

High speed steels (continuous cutting only)

•

Martensitic stainless steels

•

Cobalt and nickel based hard facing alloys

•

Fully pearlitic grey cast iron

DR-75, 85, 95, 400, 650 & 900, are high CBN content materials, diffusion bonded

at the manufacturing stage to a tungsten carbide substrate. This substrate enables

flexibility in tool fabrication,making it possible to apply a high PCBN content material

where the solid indexable format of DR-100 is not suitable.

DR-75, 85, 95 & 650 are high PCBN cutting grades and machine hardened steels

with apparent ease because, using relatively high surface speeds, heat is generated

at the point of cutting so that the PCBN tool cuts locally softened material. The heat

is carried away from the workpiece by the chip, which rapidly air-cools to provide a

brittle and harmless swarf, and the CBN tool, which has a high thermal conductivity.

This leaves the component cool, with its hardness unaffected.

DR-75 will machine Cast Iron that is not fully Pearlitic. It is not so vulnerable to

Adhesion of sticky Ferrite.

DR-85 works well machining Pearlitic Grey Cast Irons. Excellent tool life can be

achieved especially in finish milling and boring. DR-85 also provides good tool life

machining high alloy Powder Metal components.

DR-95 works well machining Pearlitic Grey Cast irons but Excels machining heat

treated, chilled and alloyed cast irons. It is also recommended for Cobalt Chrome and

Nickel Chrome alloys.

DR-650 contains TiN and has a larger CBN particle size. This is a tougher grade that

still maintains the ability to achieve small depths of cut, whilst still achieving efficient

machining. It works well interrupted cutting.

DR-400 is a high CBN content material with very good toughness. It is used when

nothing else will work due to unstable cutting conditions or severe interrupted

cutting.

DR-900 is DR-100 with a Tungsten Carbide substrate. It is useful for making tools

that can be used where the solid Cutting Tool Insert format of DR-100 is not

applicable.

Although these grades are tough, vibration or deflection will result in reduced tool life

and poor quality components. While they have been used on some very antiquated

machines with excellent results, rigidity is essential for success. Tool holders should

be as large as possible and in good condition. Coolant has little effect on the cutting

mechanism since the heat generated in the shear zone is sufficient to vaporise any

coolant provided.

Coolant does, however, serve two major purposes:-

If a substantial amount of material is to be removed, and a number of passes will be

required, or any heating of the component will make measuring the part difficult,

coolant can be used to stabilize the temperature of the workpiece. Coolant can be

used to drive the swarf away from the shear zone where it might interfere with the

cutting edge. Coolant should not be used for interrupted cutting

any hardened materials.

Applying

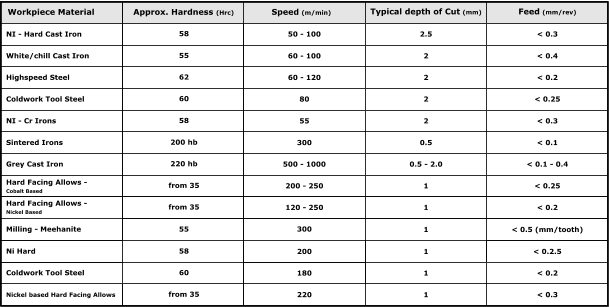

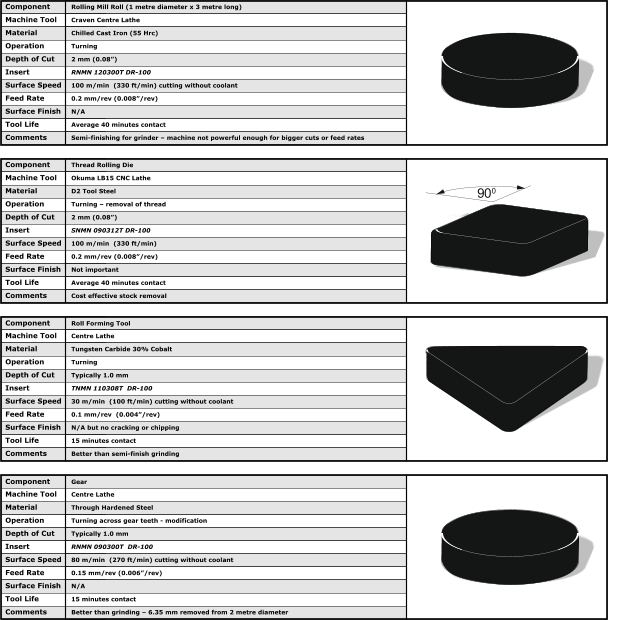

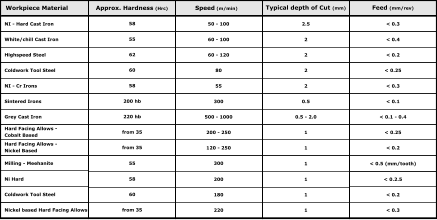

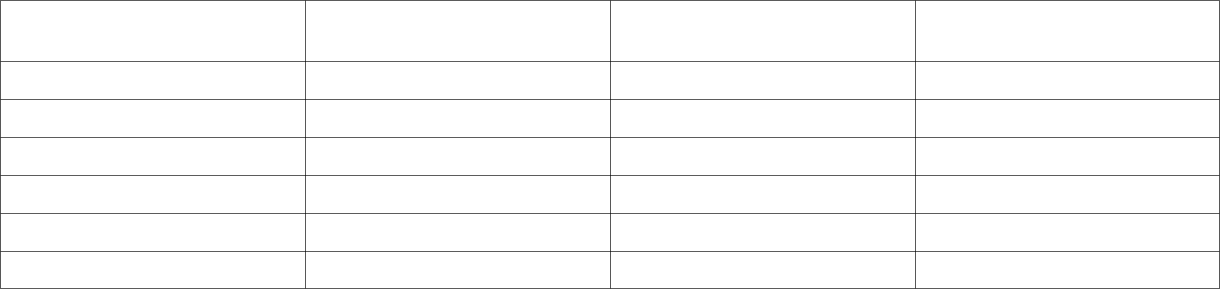

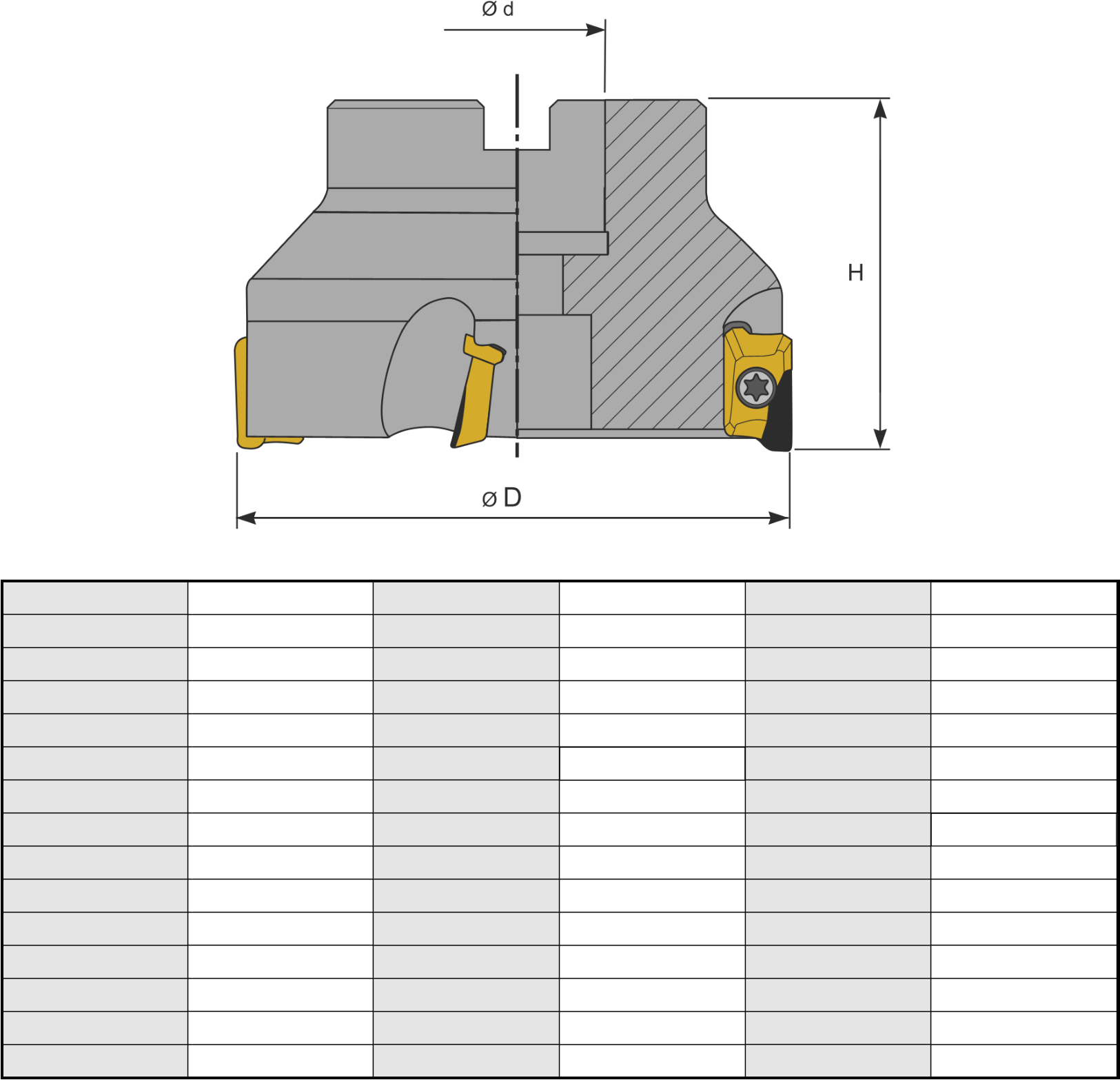

Workpiece Material

Speed (m/min)

NI - Hard Cast Iron

58

Typical depth of Cut (mm)

Feed (mm/rev)

Approximate Hardness (Hrc)

White/chill Cast Iron

Highspeed Steel

Coldwork Tool Steel

NI - Cr Irons

Sintered Irons

Grey Cast Iron

Hard Facing Allows - Cobalt Based

Hard Facing Allows - Nickel Based

Milling - Meehanite

Nickel based Hard

Facing Allows

50 - 100

2.5

< 0.3

55

60 - 100

2

< 0.4

62

60 - 120

2

< 0.2

60

80

2

< 0.25

58

55

2

< 0.3

200 hb

300

0.5

< 0.1

220 hb

500 - 1000

0.5 - 2.0

< 0.1 - 0.4

from 35

200 - 250

1

< 0.25

from 35

120 - 250

1

< 0.2

55

300

1

< 0.5 (mm/tooth)

58

1

< 0.2.5

60

180

1

< 0.2

from 35

220

1

< 0.3

Coldwork Tool Steel

Ni Hard

200

Application Examples

Cast Iron Compressor Flange

Makino Horizontal Machining Centre

Grade 17 grey cast iron

Face Milling – Fly Cutting

0.2 mm

CNMA 120412T DE DR-50

800 m/min (2670 ft/min) cutting without coolant

0.1 mm/rev (0.004”/rev)

N/A

Must be better than 0.8 Ra (32 Cla)

Average 300 minutes contact

Selector Shaft End Bracket

Mazak Quickturn 8 2 axis CNC Lathe

Case Hardened EN8

Boring – Interrupted Cut (20 mm diameter 36 mm deep)

0.2 mm

TBMN 060106T DR-450

150 m/min

0.08 mm/rev

Must be better than 0.8 Ra (32 Cla)

800 parts

Tool life more consistent than DR-50

Cam rotor

Cincinnati Sabre Vertical machining Centre

EN36B (14NiCr14) (AISI 3415) Case hardened to 58/62 Hrc

Fly cutting (Milling)

0.175 mm (0.007”)

TNMN 160308T DE DR-50

100 m/min (330 ft/min) cutting without coolant

0.05 mm/rev (0.002”/rev)

Must be better than 0.8 Ra (32 Cla)

2 parts

Transmission Component

Mazak AJV Machining Centre

Case hardened EN36B

Boring Dowel holes in Flange face

0.1 mm

EPMW 040204T CE DR-450

100 m/min

0.04 mm/rev

Not important

180 holes - Dia. 8mm, 10 mm deep

Achieves Jig Grinding tolerances in boring cycle time

Takes longer to load part than to machine it, as opposed to 1 Days grinding &

there is no danger of surface abuse

DR-85/95/400 & 650 Applications

Typical Machining Parameters

WHEN NOT TO USE ‘CBN’

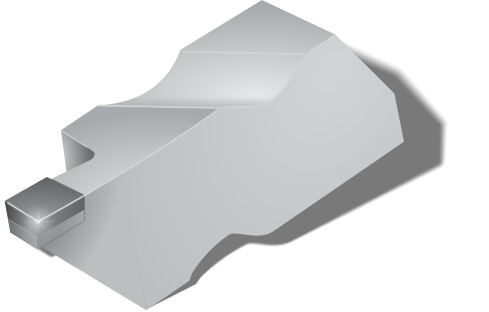

DR-100 Applications

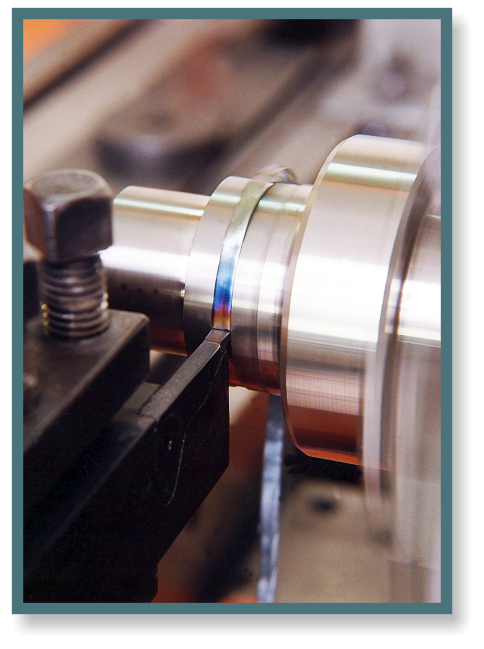

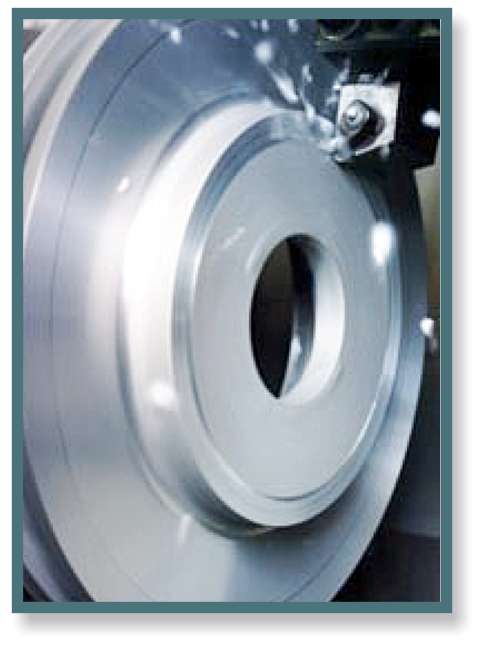

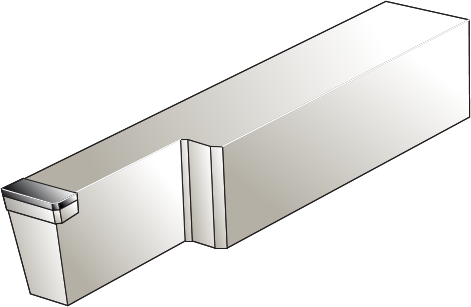

DR-100 has a high CBN content, 99%, and is supplied as solid I.S.O format indexable inserts for top clamp tool holders. PCBN cutting tools machine hardened steels with apparent ease

because, using relatively highsurface speeds, heat is generated at the point of cutting so the PCBN tool cuts locally softened material.

Using negative rake tool geometries to provide a strong edge, the heat is carried away from the work pieceby the chip, which rapidly air cools to provide a brittle and harmless swarf, and

the DR-100 insert, which has a very high thermal conductivity. This leaves the component cool, with its hardness unaffected.

Cutting forces are similar to those experienced by hard metal cutting tools machining soft steel. DR-100 should be used as a roughing or semi-finishing tool for hardened steel. Where a light depth of cut (less

than 0.50 mm) is required, a low CBN content material should be used. DR-100 machines fully Pearlitic cast iron, rough and finish, where the solid insert format allows. Although DR-100 is tough, vibration or

deflection will result in poor tool life.

Coolant can be used to; drive the swarf away from the shear zone where it might interfere with the cutting edge and; keep the temperature of the part stable.

When machining hardened materials, coolant must not be used where interrupted cutting occurs, as this will thermally shock the DR-100 insert as it comes out of cut, resulting in

catastrophic failure of the tool. Coolant can be used for interrupted cutting cast iron that has not been heat treated.

For stock removal of hard (45-68 Hrc) and certain softer ferrous materials:

•

Martensitic cast irons - Ni-hard - High Chrome irons Chilled cast irons

•

Fully hardened cold-work tool steels

•

Bearing steels

•

High speed steels

•

Martenstic stainless steels

•

Cobalt and nickel based hard facing alloys

•

Fully pearlitic grey cast iron

Machining chilled Iron Roll

Applying

Typical Machining Parameters

Application Examples

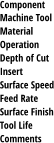

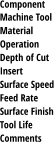

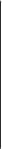

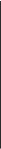

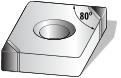

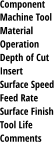

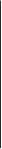

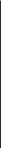

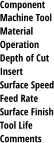

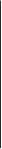

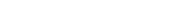

Component

Machine Tool

Material

Operation

Depth of Cut

Insert

Surface Speed

Feed Rate

Surface Finish

Tool Life

Comments

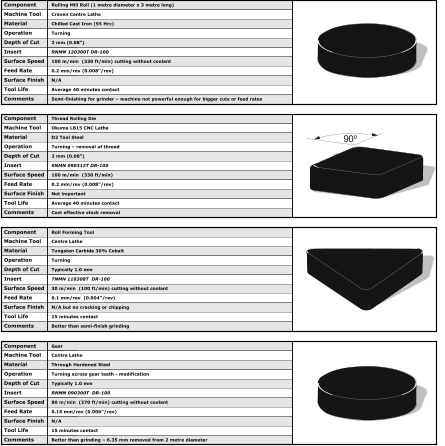

Rolling Mill Roll (1 metre diameter x 3 metre long)

Craven Centre Lathe

Chilled Cast Iron (55 Hrc)

Turning

2 mm (0.08”)

RNMN 120300T DR-100

100 m/min (330 ft/min) cutting without coolant

0.2 mm/rev (0.008”/rev)

N/A

Average 40 minutes contact

Semi-finishing for grinder – machine not powerful enough for bigger cuts or feed rates

Component

Machine Tool

Material

Operation

Depth of Cut

Insert

Surface Speed

Feed Rate

Surface Finish

Tool Life

Comments

Thread Rolling Die

Okuma LB15 CNC Lathe

D2 Tool Steel

Turning – removal of thread

2 mm (0.08”)

SNMN 090312T DR-100

100 m/min (330 ft/min)

0.2 mm/rev (0.008”/rev)

Not important

Average 40 minutes contact

Cost effective stock removal

Component

Machine Tool

Material

Operation

Depth of Cut

Insert

Surface Speed

Feed Rate

Surface Finish

Tool Life

Comments

Roll Forming Tool

Centre Lathe

Tungsten Carbide 30% Cobalt

Turning

Typically 1.0 mm

TNMN 110308T DR-100

30 m/min (100 ft/min) cutting without coolant

0.1 mm/rev (0.004”/rev)

N/A but no cracking or chipping

15 minutes contact

Better than semi-finish grinding

Component

Machine Tool

Material

Operation

Depth of Cut

Insert

Surface Speed

Feed Rate

Surface Finish

Tool Life

Comments

Gear

Centre Lathe

Through Hardened Steel

Turning across gear teeth - modification

Typically 1.0 mm

RNMN 090300T DR-100

80 m/min (270 ft/min) cutting without coolant

0.15 mm/rev (0.006”/rev)

N/A

15 minutes contact

Better than grinding – 6.35 mm removed from 2 metre diameter

WHEN NOT TO USE ‘CBN’

For stock removal of hard (45-68 Hrc) and certain softer ferrous materials:

•

Martensitic cast irons - Ni-hard - High Chrome irons Chilled cast irons

•

Fully hardened cold-work tool steels

•

Bearing steels

•

High speed steels

•

Martenstic stainless steels

•

Cobalt and nickel based hard facing alloys

•

Fully pearlitic grey cast iron

DR-100 Applications

Applying

DR-100 has a high CBN content, 99%, and is supplied as solid I.S.O format indexable inserts for top clamp

tool holders. PCBN cutting tools machine hardened steels with apparent ease because, using relatively

highsurface speeds, heat is generated at the point of cutting so the PCBN tool cuts locally softened

material.

Using negative rake tool geometries to provide a strong edge, the heat is carried away from the work

pieceby the chip, which rapidly air cools to provide a brittle and harmless swarf, and the DR-100 insert,

which has a very high thermal conductivity. This leaves the component cool, with its hardness unaffected.

Cutting forces are similar to those experienced by hard metal cutting tools machining soft steel. DR-100 should be used

as a roughing or semi-finishing tool for hardened steel. Where a light depth of cut (less than 0.50 mm) is required, a

low CBN content material should be used. DR-100 machines fully Pearlitic cast iron, rough and finish, where the solid

insert format allows. Although DR-100 is tough, vibration or deflection will result in poor tool life.

Coolant can be used to; drive the swarf away from the shear zone where it might interfere with the cutting edge and;

keep the temperature of the part stable.

When machining hardened materials, coolant must not be used where interrupted cutting occurs, as this

will thermally shock the DR-100 insert as it comes out of cut, resulting in catastrophic failure of the tool.

Coolant can be used for interrupted cutting cast iron that has not been heat treated.

Machining chilled Iron Roll

Typical Machining Parameters

Application Examples

WHEN NOT TO USE ‘CBN’

For stock removal of hard (45-68 Hrc) and certain

softer ferrous materials:

Rough Machining - DR-100

•

Martensitic cast irons - Ni-hard - High

Chrome irons Chilled cast irons

•

Fully hardened cold-work tool steels

•

Bearing steels

•

High speed steels

•

Martenstic stainless steels

•

Cobalt and nickel based hard facing alloys

•

Fully pearlitic grey cast iron

Machining chilled Iron Roll

DR-100 has a high CBN content, 99%, and is supplied as solid I.S.O format

indexable inserts for top clamp tool holders. PCBN cutting tools machine

hardened steels with apparent ease because, using relatively highsurface

speeds, heat is generated at the point of cutting so the PCBN tool cuts

locally softened material.

Using negative rake tool geometries to provide a strong edge, the heat is

carried away from the work pieceby the chip, which rapidly air cools to

provide a brittle and harmless swarf, and the DR-100 insert, which has a

very high thermal conductivity. This leaves the component cool, with

its hardness unaffected.

Cutting forces are similar to those experienced by hard metal cutting tools machining

soft steel. DR-100 should be used as a roughing or semi-finishing tool for hardened

steel. Where a light depth of cut (less than 0.50 mm) is required, a low CBN content

material should be used. DR-100 machines fully Pearlitic cast iron, rough and finish,

where the solid insert format allows. Although DR-100 is tough, vibration or

deflection will result in poor tool life.

Coolant can be used to; drive the swarf away from the shear zone where it might

interfere with the cutting edge and; keep the temperature of the part stable.

When machining hardened materials, coolant must not be used where

interrupted cutting occurs, as this will thermally shock the DR-100 insert as

it comes out of cut, resulting in catastrophic failure of the tool. Coolant can

be used for interrupted cutting cast iron that has not been heat treated.

Applying

Typical Machining Parameters

WHEN NOT TO USE ‘CBN’

Application Examples

What is Polycrystalline Diamond?

When compared to other cutting tool materials, there are three main reasons for using DR-PCD tools:-

•

Increased tool life results in reduced tool cost per component and less idle machine time.

•

Increasing cutting speed improves productivity through reduced cycle times.

•

Grinding and other less productive machining methods can be replaced by DR-PCD milling and turning.

David Richards generally offer 2 grades of PCD:-

•

DR-PCD is nominally 10-micron diamond particles in a homogeneous structure synthesised using a Cobalt catalyst. It produces good edge quality by grinding and

EDM techniques.

•

MM DR-PCD is a “Multimodal” material with a broader spectrum of particle sizes. This produces a denser material which is tougher and has better wear resistance.

However, inevitably, it is more difficult to grind and EDM, and MM tools are therefore more expensive.

Diamond is the hardest, most abrasive-resistant, material known to man. These properties make

diamond an ideal cutting tool. Within the crystal structure, however, fracture planes, used by the

jeweller to produce the gem diamond from the rough, can cause catastrophic breakage of the

tool edge, when subjected to impact.

DR-PCD tools incorporate Polycrystalline Diamond blanks, produced under conditions of high pressure, 1 million PSI,

and temperature, 1700 Degrees C, like those of natural diamond formation. Randomly orientated, carefully selected

synthetic diamond crystals are grown together on a hard metal substrate. This results in a material with the hardness,

abrasive resistance and high thermal conductivity of diamond with the toughness of hard metal.

Using the hard metal substrate the PCD blank is brazed to a carrier, either steel or hard metal and machined by

grinding or E.D.M to produce the cutting edge.

Machining MMC Brake Disc

Why Use it?

Applications

•

Machining Non Ferrous Metals and Alloys including Metal Matrix Composites.

•

Machining Plastics, Rubber, Fibre Reinforced Plastics and Composites.

•

Machining Chipboard, MDF and Natural Woods.

•

Wear Pads, Gauging Points and Probes.

Appyling

Applied correctly, DR-PCD can offer dramatic improvements in both efficiency and product quality, but the following points should be considered:-

If conventional tools fail prematurely due to breakage, DR-PCD tools are unlikely to fair any better. If excessive vibration, inclusions in component material, or similar problems cannot be avoided, then it may

be preferable to continue breaking relatively cheap conventional tools. However, the benefits offered by DR-PCD tools can often provide the incentive to overcome these problems. DR-PCD tools may give a

tool life improvement of 100 times, paying back any extra costs in improving the machinability of the material, improving the workholding or optimising the cutting tool geometries.

Although DR-PCD is both tough and extremely hard, the cutting edges can be extremely fragile. Care must be taken to avoid chipping the cutting edges.

It should be remembered that diamond and graphite are two forms of the same element, Carbon. When diamond is produced synthetically from graphite, a catalyst is used to reduce the reaction time to a

commercially acceptable level. Suitable catalysts are iron, nickel or cobalt. Unfortunately, these elements also catalyse the transformation of diamond into graphite. Diamond is not therefore generally effective

for machining ferrous, cobalt or nickel based materials.

Since the tool life of DR-PCD Tools is generally very long, most tools are made to order. However, David Richards carry an extensive stock of commonly used I.S.O. Inserts. David Richard

representatives have comprehensive experience of ultrahard cutting tool application and will be pleased to discuss your requirements.

Quotations for non-standard products will be provided on request. David Richards also offer a refurbishment service for DR-PCD tools with a rapid response to enable the users to

minimise their inventory.

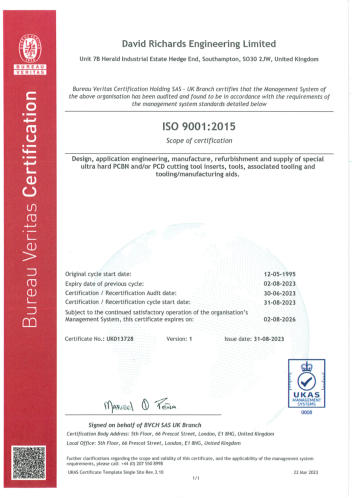

David Richards achieved accreditation to I.S.O in 1992 and remain comitted to improving quality standards.

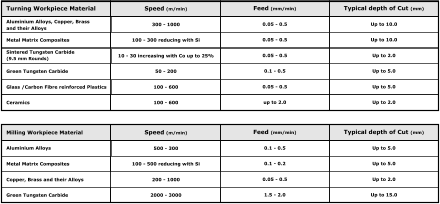

Typical Machining Parameters

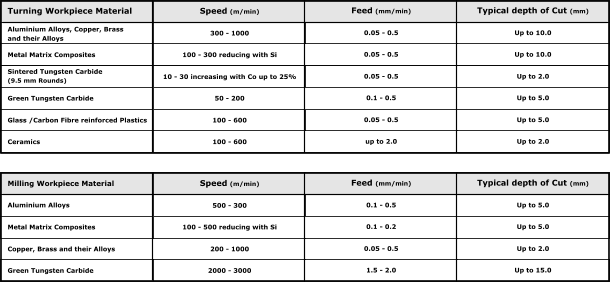

Turning Workpiece Material

Speed (m/min)

Feed (mm/min)

Typical depth of Cut (mm)

Aluminium Alloys, Copper, Brass

and their Alloys

300 - 1000

0.05 - 0.5

Up to 10.0

Metal Matrix Composites

100 - 300 reducing with Si

0.05 - 0.5

Up to 10.0

Sintered Tungsten Carbide

(9.5 mm Rounds)

10 - 30 increasing with Co up to 25%

0.05 - 0.5

Up to 2.0

Green Tungsten Carbide

50 - 200

0.1 - 0.5

Up to 5.0

Glass /Carbon Fibre reinforced Plastics

100 - 600

0.05 - 0.5

Up to 5.0

Ceramics

100 - 600

up to 2.0

Up to 2.0

Milling Workpiece Material

Speed (m/min)

Feed (mm/min)

Typical depth of Cut (mm)

Aluminium Alloys

500 - 300

0.1 - 0.5

Up to 5.0

Metal Matrix Composites

100 - 500 reducing with Si

0.1 - 0.2

Up to 5.0

Copper, Brass and their Alloys

200 - 1000

0.05 - 0.5

Up to 2.0

Green Tungsten Carbide

2000 - 3000

1.5 - 2.0

Up to 15.0

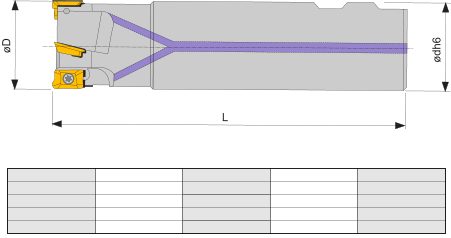

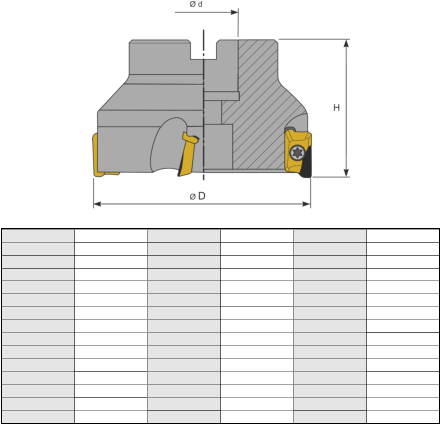

Supplied in many formats

For Engineering

•

DR-PCD tipped and ISO insert turning tools

•

DR-PCD Slot drills, end mills & milling cutter heads

•

DR-PCD tipped and ISO insert boring tools

•

DR-PCD drills and counterbore cutters

•

DR-PCD grooving and threading tools

•

DR-PCD form tools (milling and turning)

•

DR-PCD wear parts, probes and gauging points

Application Examples

Component

Machine Tool

Material

Operation

Depth of Cut

Insert

Surface Speed

Feed Rate

Surface Finish

Tool Life

Comments

Gear Box Casing

Toyoda Machining Centre

13% Silicon Aluminium

Face Milling

Typically 1.0 mm

SPKW 120404F EDR DR-PCD

800 m/min (2650 ft/min)

0.1 mm/rev/ tooth (0.004”/rev/ tooth)

0.8 micron Ra

6 months and still cutting

Axially adjustable cutter required to give best results

Component

Machine Tool

Material

Operation

Depth of Cut

Insert

Surface Speed

Feed Rate

Surface Finish

Tool Life

Comments

Door Handle

Hardinge Conquest SP T42 CNC Lathe

Hard Brass

Profiling

Typically 0.25 mm (0.01”)

VCMW 160404F DR-PCD

300 m/min (1000 ft/min)

0.05 mm/rev (0.002”/rev)

0.4 micron Ra

Thousands of components

Cosmetically superior finish

Component

Machine Tool

Material

Operation

Depth of Cut

Insert

Surface Speed

Feed Rate

Surface Finish

Tool Life

Comments

Surface Plate

Centre Lathe

Granite

Facing

Typically 0.5 mm (0.02”)

RNMN 090300F DR-PCD

60 m/min (200 ft/min)

0.1 mm/rev (0.004”/rev)

N/A

15 minutes contact

Good enough to go to lapping

Component

Machine Tool

Material

Operation

Depth of Cut

Insert

Surface Speed

Feed Rate

Surface Finish

Tool Life

Comments

Body Scanner ring

DSG Centre Lathe

Glass Reinforced Plastic

Turning

Typically 1.5 mm (0.06”)

CNMA 120408F DR-PCD

200 m/min (660 ft/min)

0.2 mm/rev (0.008”/rev)

N/A

35 minutes contact

Extremely abrasive material – 25% glass

WHEN NOT TO USE PCD

For Working Industries

•

DR-PCD router cutters

•

DR-PCD cutter blocks

•

DR-PCD saws (panel and grooving)

•

DR-PCD panel raising cutters

What is it?

Diamond is the hardest, most abrasive-resistant, material known to man.

These properties make diamond an ideal cutting tool. Within the crystal

structure, however, fracture planes, used by thejeweller to produce the

gem diamond from the rough, can cause catastrophic breakage of the

tool edge, when subjected to impact.

DR-PCD tools incorporate Polycrystalline Diamond blanks, produced under

conditions of high pressure, 1 million PSI and temperature of 1700 Degrees C,

like those of natural diamond formation. Randomly orientated, carefully selected

synthetic diamond crystals are grown together on a hard metal substrate. This

results in a material with the hardness, abrasive resistance and high thermal

conductivity of diamond with the toughness of hard metal.

Using the hard metal substrate the PCD blank is brazed to a carrier, either steel or hard metal and machined by

grinding or E.D.M to produce the cutting edge.

Machining MMC Brake Disc

Why Use it?

Applied correctly, DR-PCD can offer dramatic improvements in both efficiency and product quality, but the

following points should be considered:-

If conventional tools fail prematurely due to breakage, DR-PCD tools are unlikely to fair any better. If excessive

vibration, inclusions in component material, or similar problems cannot be avoided, then it may be preferable to

continue breaking relatively cheap conventional tools. However, the benefits offered by DR-PCD tools can often provide

the incentive to overcome these problems. DR-PCD tools may give a tool life improvement of 100 times, paying back

any extra costs in improving the machinability of the material, improving the workholding or optimising the cutting tool

geometries.

Although DR-PCD is both tough and extremely hard, the cutting edges can be extremely fragile. Care must

be taken to avoid chipping the cutting edges.

It should be remembered that diamond and graphite are two forms of the same element, Carbon. When diamond is

produced synthetically from graphite, a catalyst is used to reduce the reaction time to a commercially acceptable level.

Suitable catalysts are iron, nickel or cobalt. Unfortunately, these elements also catalyse the transformation of diamond

into graphite. Diamond is not therefore generally effective for machining ferrous, cobalt or nickel based materials.

Since the tool life of DR-PCD Tools is generally very long, most tools are made to order. However, David

Richards carry an extensive stock of commonly used I.S.O. Inserts. David Richard representatives have

comprehensive experience of ultrahard cutting tool application and will be pleased to discuss your

requirements.

Quotations for non-standard products will be provided on request. David Richards also offer a

refurbishment service for DR-PCD tools with a rapid response to enable the users to minimise their

inventory.

David Richards achieved accreditation to I.S.O in 1992 and remain comitted to improving quality standards.

Applications

Applying

Typical Machining Parameters

WHEN NOT TO USE ‘PCD’

Supplied in many formats

For Engineering

•

DR-PCD tipped and ISO insert turning tools

•

DR-PCD Slot drills, end mills & milling cutter heads

•

DR-PCD tipped and ISO insert boring tools

•

DR-PCD drills and counterbore cutters

•

DR-PCD grooving and threading tools

•

DR-PCD form tools (milling and turning)

•

DR-PCD wear parts, probes and gauging points

For Working Industries

•

DR-PCD router cutters

•

DR-PCD cutter blocks

•

DR-PCD saws (panel and grooving)

•

DR-PCD panel raising cutters

Application Examples

When compared to other cutting tool materials, there are three main reasons for using DR-PCD tools:-

•

Increased tool life results in reduced tool cost per component and less idle machine time.

•

Increasing cutting speed improves productivity through reduced cycle times.

•

Grinding and other less productive machining methods can be replaced by DR-PCD

milling and turning.

David Richards generally offer 2 grades of PCD:-

•

DR-PCD is nominally 10-micron diamond particles in a homogeneous structure synthesised using a

Cobalt catalyst. It produces good edge quality by grinding and EDM techniques.

•

MM DR-PCD is a “Multimodal” material with a broader spectrum of particle sizes. This produces a

denser material which is tougher and has better wear resistance. However, inevitably, it is more

difficult to grind and EDM, and MM tools are therefore more expensive.

•

Machining Non Ferrous Metals and Alloys including Metal Matrix Composites.

•

Machining Plastics, Rubber, Fibre Reinforced Plastics and Composites.

•

Machining Chipboard, MDF and Natural Woods.

•

Wear Pads, Gauging Points and Probes.

What Is It?

Machining MMC Brake Disc

Diamond is the hardest, most abrasive resistant,

material known to man. These properties make

diamond an ideal cutting tool. Within the crystal

structure, however, fracture planes, used by the

jeweller to produce the gem diamond from the

rough, can cause catastrophic breakage of the

tool edge, when subjected to impact.

DR-PCD tools incorporate Polycrystalline Diamond

blanks, produced under conditions of high pressure,

1 million PSI and temperature of 1700 Degrees C, like

those of natural diamond formation. Randomly

orientated, carefully selected synthetic diamond

crystals are grown together on a hard metal

substrate.

This results in a material with the hardness, abrasive resistance and high thermal

conductivity of diamond with the toughness of hard metal.

Using the hard metal substrate the PCD blank is brazed to a carrier, either steel or hard

metal and machined by grinding or E.D.M to produce the cutting edge.

Why Use it?

Applied correctly, DR-PCD can offer dramatic improvements in both efficiency

and product quality, but the following points should be considered:-

If conventional tools fail prematurely due to breakage, DR-PCD tools are unlikely to

fair any better. If excessive vibration, inclusions in component material, or similar

problems cannot be avoided, then it may be preferable to continue breaking relatively

cheap conventional tools. However, the benefits offered by DR-PCD tools can often

provide the incentive to overcome these problems. DR-PCD tools may give a tool life

improvement of 100 times, paying back any extra costs in improving the machinability

of the material, improving the workholding or optimising the cutting tool geometries.

Although DR-PCD is both tough and extremely hard, the cutting edges can be

extremely fragile. Care must be taken to avoid chipping the cutting edges.

It should be remembered that diamond and graphite are two forms of the same

element, Carbon. When diamond is produced synthetically from graphite, a catalyst is

used to reduce the reaction time to a commercially acceptable level. Suitable catalysts

are iron, nickel or cobalt. Unfortunately, these elements also catalyse the

transformation of diamond into graphite. Diamond is not therefore generally effective

for machining ferrous, cobalt or nickel based materials.

Since the tool life of DR-PCD Tools is generally very long, most tools are made

to order. However, David Richards carry an extensive stock of commonly used

I.S.O. Inserts. David Richard representatives have comprehensive experience

of ultrahard cutting tool application and will be pleased to discuss your

requirements.

Quotations for non-standard products will be provided on request. David

Richards also offer a refurbishment service for DR-PCD tools with a rapid

response to enable the users to minimise their inventory.

David Richards achieved accreditation to I.S.O in 1992 and remain comitted

to improving quality standards.

Applications

When compared to other cutting tool materials, there are three main reasons for

using DR-PCD tools:-

•

Increased tool life results in reduced tool cost per component and

less idle machine time.

•

Increasing cutting speed improves productivity through

reduced cycle times.

•

Grinding and other less productive machining methods can be replaced

by DR-PCD milling and turning.

David Richards generally offer 2 grades of PCD:-

•

DR-PCD is nominally 10-micron diamond particles in a homogeneous

structure synthesised using a Cobalt catalyst. It produces good edge

quality by grinding and EDM techniques.

•

MM DR-PCD is a “Multimodal” material with a broader spectrum of

particle sizes. This produces a denser material which is tougher and

has better wear resistance.

However, inevitably, it is more difficult to grind and EDM, and MM tools

are therefore more expensive.

•

Machining Non Ferrous Metals and Alloys including Metal

Matrix Composites.

•

Machining Plastics, Rubber, Fibre Reinforced Plastics and Composites.

•

Machining Chipboard, MDF and Natural Woods.

•

Wear Pads, Gauging Points and Probes.

Applying

Typical Machining Parameters

Supplied in many formats

For Engineering

•

DR-PCD tipped and ISO insert turning tools

•

DR-PCD Slot drills, end mills & milling cutter heads

•

DR-PCD tipped and ISO insert boring tools

•

DR-PCD drills and counterbore cutters

•

DR-PCD grooving and threading tools

•

DR-PCD form tools (milling and turning)

•

DR-PCD wear parts, probes and gauging points

For Working Industries

•

DR-PCD router cutters

•

DR-PCD cutter blocks

•

DR-PCD saws (panel and grooving)

•

DR-PCD panel raising cutters

WHEN NOT TO USE ‘PCD’

Application Examples

Machining Cast Iron

PCBN can provide a cost effective and highly productive alternative to hard metal or ceramic cutting tools for the machining of cast irons.

In general terms, the following factors should be considered when applying PCBN to an ironcomponent. Cast iron is not generally very hard

(less than HRc.30) but tends to be abrasive. PCBN is therefore employed because of its abrasive resistance. Unless the iron has been chilled or

deliberately heat treated, the cutting action will be such that the PCBN will not be required to anneal the material being cut in the shear zone.

Grey cast irons are often fully pearlitic in structure - Grade 14 & 17 are common.

In this case, the best results are gained using DR-100, 95 or 85 at surface speeds above 400 m/min. If the machine tool or component limit the speed

available to less than 400 m/min, DR-50 becomes more cost effective. Tool life and component quality improvements are often dramatic and more than

justify the increased cost of the PCBN tools. If the grey cast iron is not fully pearlitic and more free ferrite is present within the structure, the

machinability of the iron becomes more difficult to predict. As the level of “soft and sticky” ferrite increases, the DR-100, 95 or 85 tool is more

likely to suffer adhesion or “pick up” which will alter the cutting action, resulting in premature wear of the tool. DR-75 is less prone to adhesion and

can offer a cost effective option.

DR-75 becomes more likely to provide good results as the level of free ferrite increases and a short trial will soon determine

the most suitable PCBN material.

Fully ferritic grey cast irons are not generally cost effective PCBN applications. S.G. irons are usually soft (less than HRc.30 ) and fully ferritic. PCBN is therefore not often as efficient as other

cutting tool materials.

There has, however, been a tendency to produce S.G. irons (nodular irons) with a pearlitic structure. This has resulted in some nominally S.G. irons machining surprisingly well with

PCBN, DR-50 tending to be more successful.

Low alloy irons commonly used in the automotive industry can be machined with PCBN, but the performance is again dependant on the level of free ferrite in the structure.

Hardened irons, either heat treated or alloyed and heat treated, are machined in the same manner as hardened steels and are therefore more predictable.

Cutting speeds recommended are lower - less than 200 m/min.

It must be remembered that cast iron of a given specification produced by a foundry on one day may have a different machinabilty to that produced the next day.

Once the benefits of machining with PCBN have been determined, it may be considered worthwhile ensuring that castings supplied to the machine shop have a suitable

microstructure to guarantee consistent PCBN tool performance.

If the structure or grade of cast iron is unknown, a simple trial will soon determine the suitability of PCBN as a cutting tool.

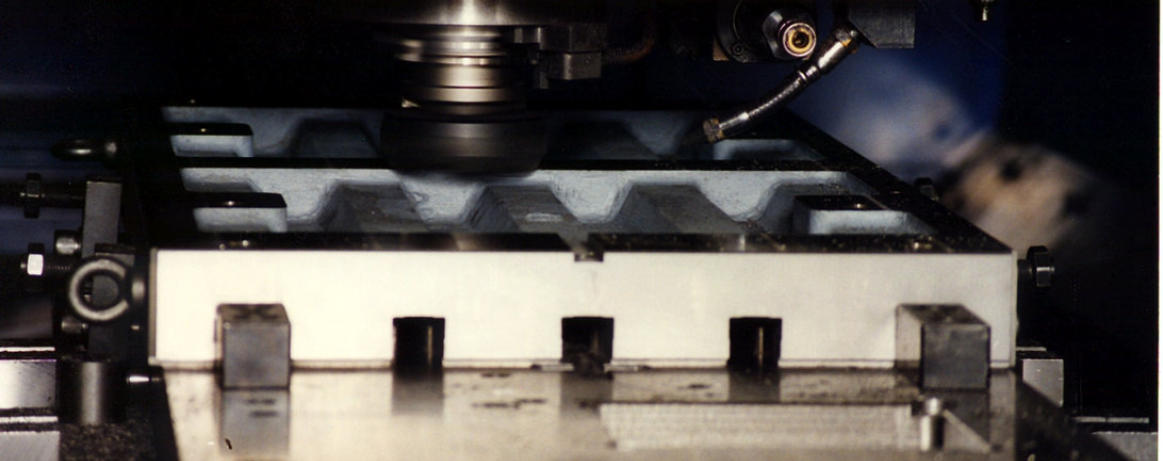

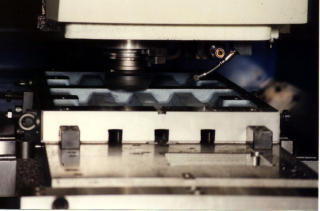

Finish Boring Grade 17 Cast Iron Cheek Plates

Flycutting Machining Centre Tables

PCBN can provide a cost effective and highly productive alternative to hard

metal or ceramic cutting tools for the machining of cast irons.

In general terms, the following factors should be considered when applying PCBN to

an ironcomponent. Cast iron is not generally very hard (less than HRc.30) but tends

to be abrasive. PCBN is therefore employed because of its abrasive resistance.

Unless the iron has been chilled or deliberately heat treated, the cutting action will

be such that the PCBN will not be required to anneal the material being cut in

the shear zone.

Grey cast irons are often fully pearlitic in structure -

Grade 14 & 17 are common.

In this case, the best results are gained using DR-100, 95 or 85 at surface speeds above 400 m/min. If the machine tool

or component limit the speed available to less than 400 m/min, DR-50 becomes more cost effective. Tool life and

component quality improvements are often dramatic and more than justify the increased cost of the PCBN tools.

If the grey cast iron is not fully pearlitic and more free ferrite is present within the structure, the machinability of the iron

becomes more difficult to predict. As the level of “soft and sticky” ferrite increases, the DR-100, 95 or 85 tool is more

likely to suffer adhesion or “pick up” which will alter the cutting action, resulting in premature wear of the tool.

DR-75 is less prone to adhesion and can offer a cost effective option.

DR-75 becomes more likely to provide good results as the level of free ferrite increases and a short trial will

soon determine the most suitable PCBN material.

Fully ferritic grey cast irons are not generally cost effective PCBN applications. S.G. irons are usually soft (less than

HRc.30 ) and fully ferritic. PCBN is therefore not often as efficient as other cutting tool materials.

There has, however, been a tendency to produce S.G. irons (nodular irons) with a pearlitic structure. This has

resulted in some nominally S.G. irons machining surprisingly well with PCBN, DR-50 tending

to be more successful.

Low alloy irons commonly used in the automotive industry can be machined with PCBN, but the

performance is again dependant on the level of free ferrite in the structure.

Hardened irons, either heat treated or alloyed and heat treated, are machined in the same manner as hardened steels

and are therefore more predictable.

Cutting speeds recommended are lower - less than 200 m/min.

It must be remembered that cast iron of a given

specification produced by a foundry on one day may

have a different machinabilty to that produced the

next day.

Once the benefits of machining with PCBN have

been determined, it may be considered

worthwhile ensuring that castings supplied to

the machine shop have a suitable microstructure

to guarantee consistent PCBN tool performance.

If the structure or grade of cast iron is unknown,

a simple trial will soon determine the suitability

of PCBN as a cutting tool.

Machining Cast Iron

Finish Boring Grade 17 Cast Iron Cheek Plates

Flycutting Machining Centre Tables

PCBN can provide a cost effective and highly

productive alternative to hard metal or

ceramic cutting tools for the machining of

cast irons.

In general terms, the following factors should be

considered when applying PCBN to an

ironcomponent.

Cast iron is not generally very hard (less than

HRc.30) but tends to be abrasive. PCBN is

therefore employed because of its abrasive

resistance.

Finish Boring Grade 17 Cast Iron Cheek Plates

Unless the iron has been chilled or deliberately heat treated, the cutting action will be

such that the PCBN will not be required to anneal the material being cut in

the shear zone.

Grey cast irons are often fully pearlitic in structure - Grade 14 & 17 are

common.

In this case, the best results are gained using DR-100, 95 or 85 at surface speeds

above 400 m/min. If the machine tool or component limit the speed available to less